2. Features asymmetric bidirectional sealing structure with integrated oil reservoir for compact piston sealing;

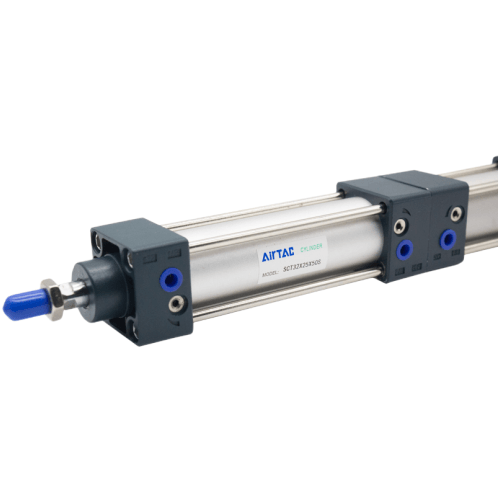

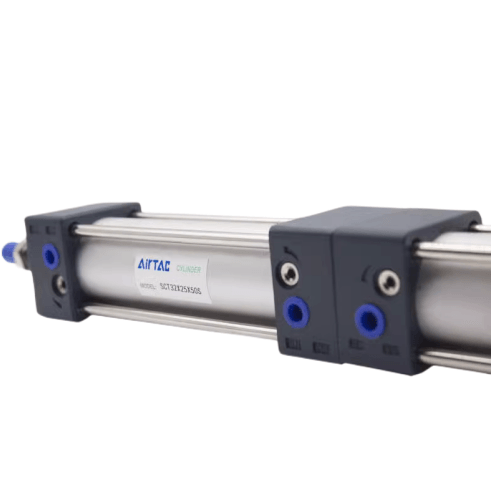

3. Tie-rod construction with aluminum tube barrel and reinforced end caps connected via precision tie-rods for enhanced structural integrity;

4. Multi-positional locking capability throughout the stroke cycle;

5. Precision-adjustable pneumatic cushioning system;

6. Available in multiple bore sizes (SCT32-SCT63) with configurable mounting accessories;

7. High-temperature resistant seals enable operational range of 0-150°C.

Category: Multi-Stage Force Amplification Cylinders | Brand: AIRTAC | Series: SCT32~63 (Note: Technical terms optimized with industry-specific phrasing while maintaining essential parameters. Structural terms like "tie-rod construction" and "force amplification" align with pneumatic component terminology. Temperature specification follows international unit standards.)

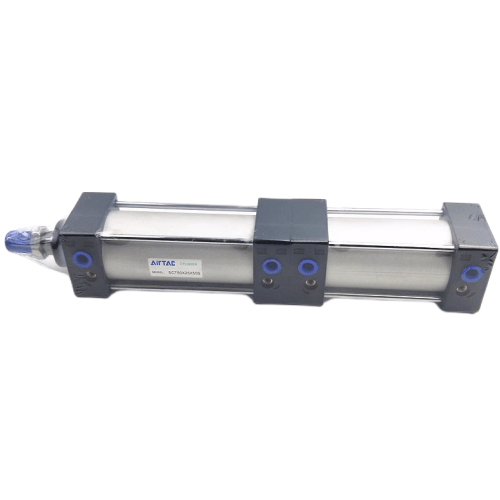

AirTAC SCT32~63 Multi-Position Force Amplification Cylinder - SCT50X400X200S

- Model Series: SCT32~63 (Standard configuration)

- Specific Model: SCT50X400X200S

- Bore Size: 50mm (Φ50)

- Stroke: 400mm (±0.5mm tolerance)

- Mounting Spacing: 200mm center-to-center

- Working Pressure: 0.1-1.0 MPa (14.5-145 PSI)

- Temperature Range: -10℃ to 80℃ (14°F to 176°F)

- Air Supply: Lubricated or non-lubricated (requires 40μm filtration)

- Repeat Positioning Accuracy: ±0.2mm

- Max Piston Speed: 500-800 mm/s

- Buffer Type: Adjustable hydraulic cushion (both ends)

- Port Size: G3/8 (BSPP thread)

- Material: Cylinder body - Aluminum alloy AL6063; Piston rod - Chrome-plated steel

- Seal Material: High-temperature NBR + Polyurethane

- Weight: 5.8 kg (12.8 lbs) ±3%

- Dimensions (L×W×H): 620mm × 108mm × 108mm (Extended length including rod)

- Protection Class: IP54 (standard sealing)

- Mounting Options: Front flange MF1, rear flange MF2, or foot mounting

High-force multi-position pneumatic actuator with precision guided piston structure, featuring twin-rod configuration for balanced load distribution. The dual-chamber design enables force amplification through simultaneous air pressure application. Integrated magnetic slots allow for position feedback sensor installation (sensors sold separately). Requires 1-2 drops of ISO VG32 oil per cycle if using non-lubricated air.

- Press-fit operations in automotive transmission assembly

- Multi-stage clamping systems for CNC machining centers

- High-torque valve actuation in chemical processing

- Packaging machinery requiring sequenced compression forces

- Automated stamping/punching systems with position hold

| Property | Property Value |

|---|---|

| sku | SCT50X400X200S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | S-Magnetic |

| Bore Diameter | <50mm> |

| Stroke | <400mm> |

| Stroke | <200mm> |

Rücksendungen unbenutzter Artikel werden innerhalb von 15 Tagen nach Erhalt oder Erhalt der Sendungsnummer akzeptiert. Sie als Kunde sind verpflichtet, uns vor der Rücksendung per E-Mail zu informieren, jedoch nur in folgenden Fällen:

- Ich habe den falschen Artikel erhalten.

- Der Artikel entsprach nicht den Erwartungen (z. B. beschädigte Verpackung).

- Der Artikel wies Mängel auf.

- Überschreitung der Lieferzeit.

- Der Versender gestattet keine Warenprüfung vor der Bezahlung.

Die zurückgesendeten Produkte müssen sich in der Originalverpackung befinden, sicher verpackt, unbeschädigt und ungetragen sein. Das bedeutet, dass die Artikel zum Schutz während des Transports sicher in einem Karton verpackt sein müssen, idealerweise in demselben Karton, der für den Versand an Sie verwendet wurde.