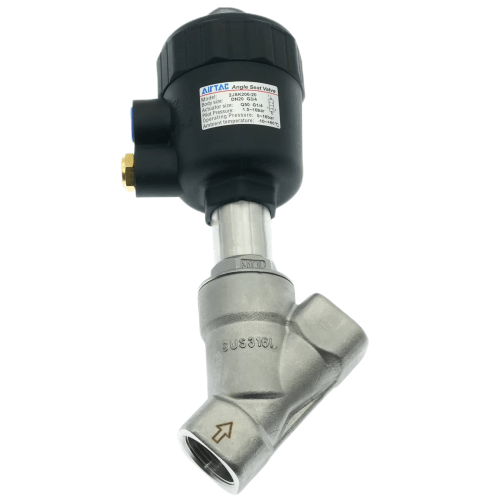

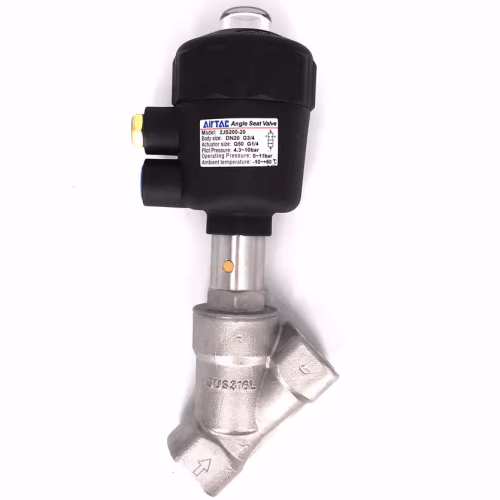

2. Stainless steel construction (body & linkage) ensures superior corrosion resistance. PTFE sealing components provide broad chemical compatibility, suitable for high-temperature and highly corrosive fluid handling.

3. Optimized 45° angle seat design with streamlined internal flow path minimizes pressure drop and ensures laminar flow for enhanced throughput. Integrated filter element in linkage prevents contamination ingress, extending service life.

4. Position indicator window enables visual monitoring and precise flow rate adjustment. Optional retrofit with limit switch or emergency manual override for enhanced functionality.

5. Recessed metal pneumatic ports with transition adaptor plate facilitate seamless installation of NAMUR-standard solenoid valves.

6. 360° rotatable actuator assembly simplifies orientation adjustment during installation.

Category: Angle Seat Valve | Brand: AIRTAC | Series: 2JS

AirTAC 2JS250-25-Q80 Angle Seat Valve Specifications

- Model: 2JS250-25-Q80

- Type: 2/2-way normally closed (pneumatic actuation)

- Port connection: G1" (BSPP thread)

- Valve diameter: DN25 (25mm)

- Operating pressure: 0.2–1.0 MPa

- Max working pressure: 10 bar

- Temperature range: -10℃ to 180℃

- Actuation pressure: 3–8 bar

- Seal material: PTFE+EPDM (FDA compliant)

- Body material: Stainless steel CF8M (316)

- Flow coefficient: Kv=45 m³/h, Cv=52

- Weight: 1.65 kg (with actuator)

- Dimensions: 152mm(L) × 102mm(W) × 118mm(H)

- Response time: ≤0.3s

- Protection rating: IP67 (actuator)

- Media compatibility: Water, steam, mild chemicals

Heavy-duty angle seat valve with 90° flow path design, optimized for high-temperature liquid and steam applications. Features zero-leakage PTFE bellows seal and anti-vibration stem design. The stainless steel construction ensures corrosion resistance in aggressive environments. Requires filtered compressed air (40μm, lubricated or non-lubricated) for actuator operation.

- Steam sterilization systems in pharmaceutical plants

- High-temperature water circulation in food processing

- Chemical dosing systems with corrosive media

- Industrial boiler feed water control

- Beverage filling line CIP (Clean-in-Place) systems

| Property | Property Value |

|---|---|

| sku | 2JS250-25-Q80 |

| Port Size | G1 |

| Flow Aperture | <25 mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.