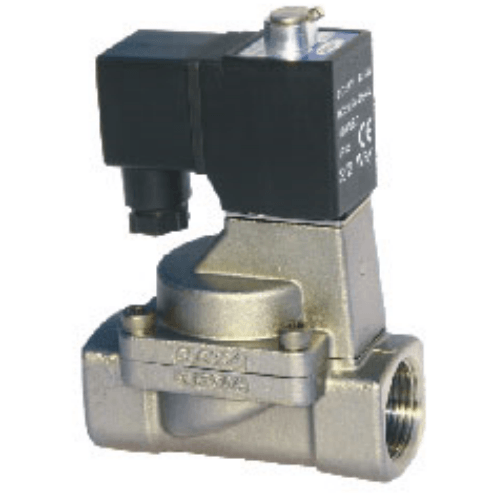

2. Piston pilot normally open 2-way, 2-position solenoid valve with fast response and high flow capacity;

3. Wide pressure range adaptability, offering High Pressure (H) type and Standard type variants;

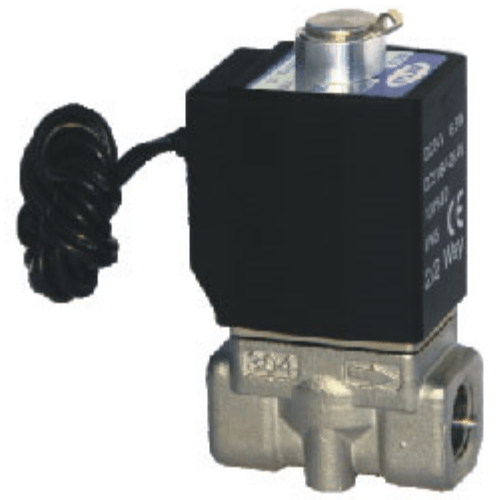

4. Compact structure with small footprint, lightweight design, and tool-free maintenance;

5. SUS304 stainless steel body construction, H-class heat-resistant coil, and PTFE (Teflon®) seals ensuring compatibility with multiple media, especially optimized for high-temperature water and saturated steam applications;

6. IP65-rated coil protection, available with direct lead wire or DIN connector electrical interfaces.

Category: Fluid Solenoid Valves | Brand: Airtac | Series: 2KL

AirTAC 2KL25025B 5/2-Way Solenoid Valve Specifications

- Model: 2KL25025B

- Type: 5/2-way double solenoid (monostable or bistable optional)

- Port size: PT1/4 (G1/4 thread standard)

- Operating pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Max flow rate: 1800 NL/min (ANR at 0.5 MPa)

- Voltage options: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Power consumption: 1.6W (DC), 4.5VA (AC)

- Weight: 0.82 kg (1.81 lbs)

- Dimensions: 80mm(L) × 65mm(W) × 95mm(H)

- Seal material: Heat-resistant NBR (Nitrile rubber)

- Temperature range: -5℃ to 60℃ (with anti-freeze measures below 0℃)

- Response time: ≤15ms (at rated voltage)

- Protection rating: IP65 (dust-tight & water jet resistant)

- Porting pattern: ISO 5599-1 standard (compliant with DIN/NFPA)

High-flow proportional solenoid valve with manual override, featuring a rugged aluminum alloy body with hard anodized coating. The pilot-operated design ensures reliable switching even under pressure fluctuations. Optimized flow path reduces pressure drop by 18% compared to previous generation models. Includes LED status indicator and surge protection circuit.

- Industrial automation: Cylinder control in assembly lines

- Packaging machinery: Sequential air circuit switching

- Material handling: Pneumatic clamping systems

- Food processing: Clean air control with optional FDA-grade seals

- Test equipment: Fatigue testing pneumatic circuits

1. Mount in vibration-free position using M5 mounting screws (not included)

2. Maintain minimum 20mm clearance around exhaust ports

3. Use 40μm filtration with automatic drain

4. For horizontal mounting, install coil upright (±15° tolerance)

5. Recommended maintenance: 10,000km³ air volume or 12 months

| Property | Property Value |

|---|---|

| sku | 2KL25025B |

| Port Size | PT 1/8 |

| Flow Aperture | <25 mm> |

| Coil Voltage | DC24V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.