2. Wide pressure range adaptability, offering Ultra-High Pressure (X), High Pressure (H), Standard, and Large Flow (L) models;

3. Compact design with minimized footprint, reduced weight, and tool-free modular assembly for easy maintenance;

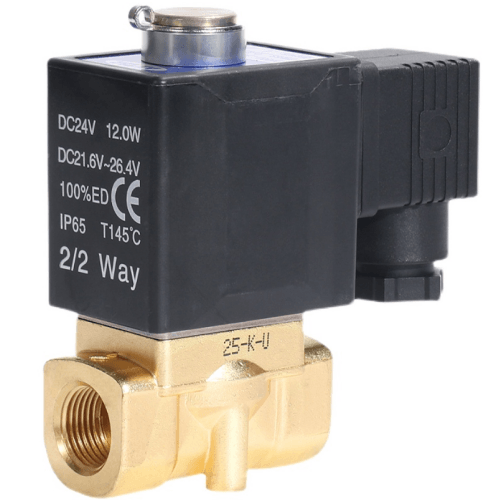

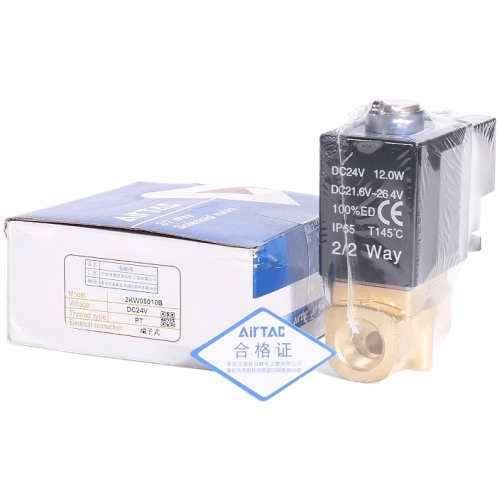

4. Brass valve body, B-class thermal-rated coil, and standard FPMF (Fluorocarbon Rubber) seals compatible with diverse media. Custom seal materials available upon consultation with technical department;

5. IP65-rated coil protection, wiring options include Lead Wire or DIN Connector configurations.

**Category**: Fluid Solenoid Valve | **Brand**: AirTAC | **Series**: 2KWL

AirTAC 2KWL03006A Fluid Solenoid Valve Specifications

- Model: 2KWL03006A

- Type: 2-position, 3-way direct-acting solenoid valve

- Port size: G1/8 (ISO228 standard)

- Thread type: Parallel (BSPP)

- Operating pressure: 0.05–1.0 MPa (7-145 psi)

- Max flow rate: 750 L/min (Cv=1.2)

- Voltage options: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Weight: 350g ±5% (including coil)

- Dimensions: 80mm(L) × 50mm(W) × 65mm(H)

- Seal material: FKM (Fluorocarbon Rubber)

- Temperature range:

- Ambient: -5℃ to 60℃ (with no freezing)

- Fluid: 0℃ to 60℃ (water/oil)

- Power consumption: 4.8W (DC24V), 5.5VA (AC220V)

- Response time: ≤15ms (open/close)

- Protection rating: IP67 (coil assembly)

- Port alignment: Inlet/Outlet on bottom, exhaust on side

High-flow fluid control valve with dual-coil latching capability, featuring corrosion-resistant brass body and manual override. Designed for water, air, and light oil applications requiring rapid cycling (up to 300,000 operations). Includes surge protection and LED status indicator (select models). Requires 25μm filtration for optimal performance.

- Industrial cleaning equipment water control

- Automotive test bench cooling systems

- Beverage dispensing machines

- Chemical dosing systems

- Hydraulic pilot stage control

- Laboratory analytical instrument fluidics

1. Mount horizontally with coil facing upward

2. Install downstream filter (25μm) and water separator

3. Allow 20mm clearance around valve for heat dissipation

4. Use PTFE tape on male threads only, avoiding entry into flow paths

5. Replace seals annually under continuous operation conditions

Water (≤60℃), ISO VG32 hydraulic oil, compressed air (lubricated/non-lubricated),

Ethylene glycol mixtures (≤40% concentration), mild alkaline solutions (pH 5-9)

| Property | Property Value |

|---|---|

| sku | 2KWL03006A |

| Port Size | PT1/8 |

| Flow Aperture | <4mm> |

| Coil Voltage | AC220V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.