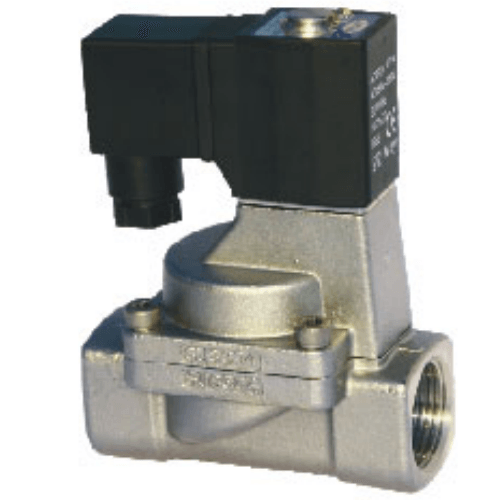

2. Pilot-operated piston type normally closed 2-port 2-way solenoid valve featuring fast actuation and high flow capacity;

3. Extended pressure range compatibility, available in high-pressure (H) and standard configurations;

4. Compact, lightweight design with space-saving dimensions for easy installation and maintenance;

5. SUS304 stainless steel body construction, Class H thermal-rated coil, and PTFE (Teflon) seals ensuring compatibility with diverse media including high-temperature water and saturated steam;

6. IP65-rated coil protection with wiring options: direct lead wire or DIN connector interface.

Category: Solenoid Valves | Brand: AIRTC | Series: 2L

AirTAC 2L50050C Solenoid Valve Technical Specifications

- Model: 2L50050C (2-position 5-way)

- Operation type: Double solenoid pilot-operated

- Port configuration: 5 ports (P, A, B, R, S)

- Port size: PT1/4 (G1/4 optional)

- Operating pressure range: 0.15–0.8 MPa (21.7–116 PSI)

- Voltage variants: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Flow coefficient (Cv): 1.8

- Maximum switching frequency: 5 Hz

- Response time: ≤20ms (at 0.5MPa)

- Seal material: HNBR (Hydrogenated Nitrile) for enhanced oil resistance

- Ambient temperature: -5℃ to 80℃ (with anti-freeze measures below 5℃)

- Protection class: IP67 (dust-tight and protected against temporary immersion)

- Electrical connection: DIN43650 Form A with LED indicator

- Weight: 420g ±5% (excluding connector)

- Dimensions: 80mm(L) × 50mm(W) × 65mm(H) (manual override protrusion adds 12mm)

- Exhaust flow capacity: 650 L/min (ANR)

- Power consumption: 1.6W (DC), 3.2VA (AC)

High-flow directional control valve with dual manual override, designed for demanding pneumatic circuits requiring bi-stable position memory. Features copper-free aluminum alloy body for compatibility with food processing environments and vacuum applications. Requires ISO 8573-1:2010 Class 3 compressed air (max 5mg/m³ oil content).

- Multi-axis robotic end effector control

- Plastic injection molding machine clamp systems

- Automated assembly line positioning cylinders

- Semiconductor wafer handling vacuum/pressure switching

- Textile machinery with frequent directional changes

| Property | Property Value |

|---|---|

| sku | 2L50050C |

| Port Size | PT2 |

| Flow Aperture | <50mm> |

| Coil Voltage | AC 110V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.