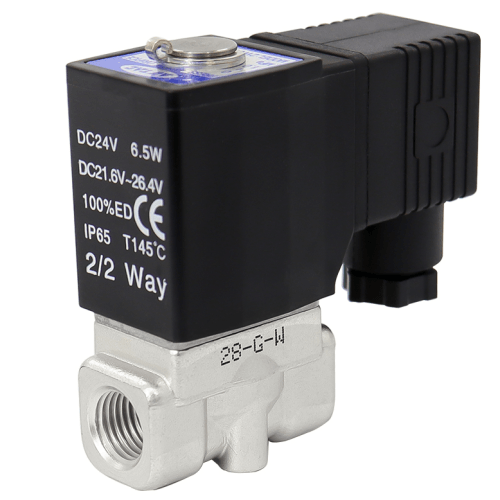

1. Direct-acting normally closed 2-port 2-position configuration, ensuring rapid and sensitive directional switching;

2. Extensive pressure range compatibility with model options: Ultra-High Pressure (X), High Pressure (H), Standard, Large Flow (L), and Extra-Large Flow (T);

3. Compact structure with minimized dimensions and lightweight design for convenient installation and maintenance;

4. SUS304 stainless steel body construction, B-class thermal-rated solenoid coil. Standard FPM (Fluororubber) seals compatible with multiple media. Custom seal materials available through our technical department;

5. IP65-rated coil protection with wiring options: direct lead wire or DIN connector.

Category: Fluid Solenoid Valves | Brand: AIRTAC | Series: 2SH

AirTAC 2SH Series High-Pressure Solenoid Valve 2SH03006B Specifications

- Model: 2SH03006B

- Type: 3-position, 5-way (double solenoid)

- Port size: 1/4" NPT (G1/8 optional)

- Operating pressure: 0.1–1.0 MPa (max burst pressure 1.5 MPa)

- Voltage options: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Weight: 680g ±3% (including coil)

- Dimensions: 108mm(L) × 52mm(W) × 53mm(H) (manual override version adds 8mm)

- Seal material: Heat-resistant FKM (fluorocarbon rubber)

- Temperature range: -10℃ to 80℃ (with FKM seals)

- Flow coefficient (Cv): 1.8 (at 0.5 MPa)

- Response time: ≤25ms (energize), ≤35ms (de-energize)

- Power consumption: 3.5W (DC), 4.5VA (AC)

- Protection rating: IP67 (coil), IP40 (valve body)

- Port thread depth: 12mm (NPT), 10mm (G)

High-pressure bi-stable solenoid valve designed for industrial automation systems requiring precise directional control under sustained pressure. Features a hardened aluminum alloy body with chrome-plated brass spool for corrosion resistance. The dual-coil design enables latching operation without continuous power consumption. Requires 5μm filtered, lubricated air (ISO 8573-1:2010 class 4.4.3).

- Hydraulic system pilot controls in injection molding machines

- High-pressure pneumatic clamping devices

- CNC machine tool fixture sequencing

- Compressed air distribution in foundry equipment

- Test bench pressure cycling systems

- Mount in vibration-free environments using M5 mounting screws

- Maintain minimum 20mm clearance around exhaust ports

- Use shielded cables for electrical connections in high-noise environments

- Replace seals every 5 million cycles (minimum) under 0.6 MPa operation

- Apply thread sealant on NPT ports (not required for G threads)

| Property | Property Value |

|---|---|

| sku | 2SH03006B |

| Port Size | PT1/8 |

| Flow Aperture | <2mm> |

| Coil Voltage | DC12V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.