Description

2V025 Series

1. Direct-acting normally closed 2-port 2-position solenoid valve with rapid and responsive switching characteristics;

2. Lightweight and compact structural design;

3. Features brass valve body construction, Class B thermal-rated electromagnetic coil, and fluorinated rubber (VITON) seals compatible with multiple media types;

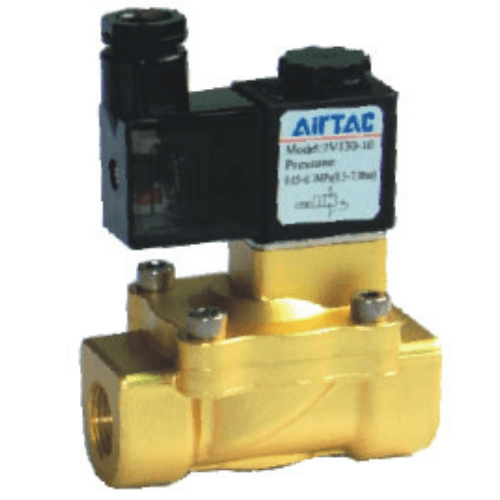

2V130/250 Series

1. Diaphragm pilot-operated 2-port 2-position solenoid valve offering low power consumption and high flow capacity;

2. Low cracking pressure requirement with minimum operating pressure differential of 0.05MPa;

3. Constructed with brass valve body, Class B thermal-rated electromagnetic coil, and Nitrile Butadiene Rubber (NBR) sealing components;

Category: Fluid Solenoid Valves | Brand: AirTAC | Series: 2V

Installation guidelines:

Installation guidelines:

1. Mount with vibration-damping pads in high-frequency environments

2. Maintain minimum 20mm clearance below valve for exhaust dispersion

3. Use copper-free lubricants if manual override is engaged weekly

4. Pair with 5μm filtration unit when handling abrasive media

Critical note:

Critical note:

Avoid continuous operation above 0.8 MPa for >4 hours. For vacuum applications (≤-0.095MPa), install check valve upstream.

1. Direct-acting normally closed 2-port 2-position solenoid valve with rapid and responsive switching characteristics;

2. Lightweight and compact structural design;

3. Features brass valve body construction, Class B thermal-rated electromagnetic coil, and fluorinated rubber (VITON) seals compatible with multiple media types;

2V130/250 Series

1. Diaphragm pilot-operated 2-port 2-position solenoid valve offering low power consumption and high flow capacity;

2. Low cracking pressure requirement with minimum operating pressure differential of 0.05MPa;

3. Constructed with brass valve body, Class B thermal-rated electromagnetic coil, and Nitrile Butadiene Rubber (NBR) sealing components;

Category: Fluid Solenoid Valves | Brand: AirTAC | Series: 2V

AirTAC 2V25020BI Fluid Control Valve Technical Details

- Model: 2V25020BI

- Type: 2-position 5-way pilot-operated solenoid valve

- Port size: PT1/4 (G1/4 optional)

- Operating pressure range: 0.05–1.0 MPa

- Max flow capacity: 1,200 NL/min (ANR)

- Voltage variants: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Response time: ≤15ms (excitation), ≤20ms (de-excitation)

- Seal materials: HNBR/Nitrile compound (standard), optional FKM/Viton for chemical resistance

- Ambient temperature: -5℃ to 60℃ (with anti-freeze measures below 0℃)

- Protection class: IP67 (dustproof & waterproof)

- Electrical connection: DIN43650 Form A with LED indicator

- Weight: 0.68 kg ±5%

- Dimensions: 59mm (H) × 44mm (W) × 105mm (L)

- Port thread depth: 12mm (minimum engagement)

- Hysteresis: ≤0.02 MPa

- Coil insulation class: Class F (155℃)

High-flow proportional control valve with zero-pressure start capability, featuring dual-coil latching design for energy efficiency. The aluminum alloy body with hard anodizing treatment ensures durability in humid environments. Includes manual override and position sensing options.

Industrial Applications:

- Automated assembly line clamping systems

- Plastic injection molding machine ejectors

- Textile machinery tension control

- Semiconductor wafer handling robots

- Beverage filling station diverters

- Automotive paint shop actuators

1. Mount with vibration-damping pads in high-frequency environments

2. Maintain minimum 20mm clearance below valve for exhaust dispersion

3. Use copper-free lubricants if manual override is engaged weekly

4. Pair with 5μm filtration unit when handling abrasive media

Avoid continuous operation above 0.8 MPa for >4 hours. For vacuum applications (≤-0.095MPa), install check valve upstream.

| Property | Property Value |

|---|---|

| sku | 2V25020BI |

| Port Size | BSPT 3/4 |

| Flow Aperture | <25 mm> |

| Coil Voltage | DC24V |

Shipping policies

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.

Reviews

Recently Viewed

Explore your recently viewed items, blending quality and style for a refined living experience.