2. Spool-type structure provides excellent sealing performance, compact size, lightweight construction, and tool-free assembly/disassembly;

3. Specially machined internal bore minimizes friction resistance while extending operational lifespan;

4. Lubrication-free maintenance;

5. Multiple mounting orientations enable flexible installation configurations;

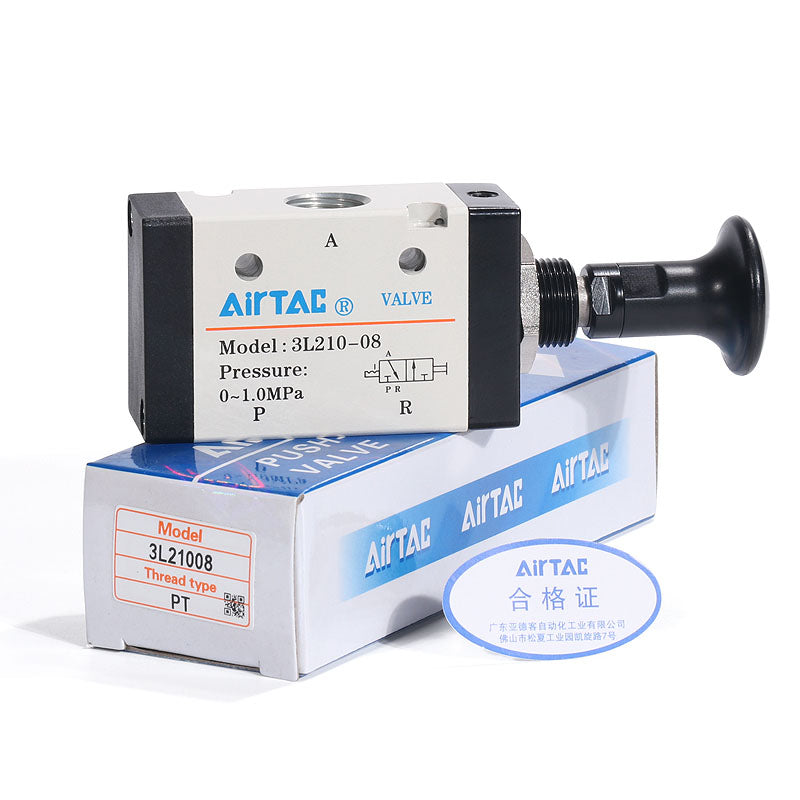

Category: Manual Pull Valve , Brand: AIRTAC , Series: 3L

AirTAC 3L110-06 Manual Pull Valve Specifications

- Model: 3L110-06

- Type: 2-position 3-way normally closed (manual override)

- Port configuration: P (pressure), A (output), R (exhaust)

- Port size: PT1/8 (G1/8 optional)

- Thread standard: BSPP (parallel threads)

- Operating pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Max flow rate: 750 L/min (Cv=0.48)

- Body material: Brass with nickel plating

- Seal material: NBR (Nitrile) rubber

- Operating temperature: -20℃ to 80℃ (-4°F to 176°F)

- Weight: 205g ±5g

- Dimensions: 50mm(L) × 25mm(W) × 40mm(H)

- Actuation force: 3-5N (manual lever operation)

- Mounting options: Direct piping or sub-base mounting

- Response time: Instantaneous (mechanical actuation)

Mechanical manual override valve designed for emergency operation or system debugging. Features positive position lock mechanism with visual position indicator. The ergonomic lever allows single-finger operation with tactile feedback. Compatible with ISO 15407-1 standards for pneumatic valves.

- Pneumatic system maintenance bypass control

- Production line emergency stop systems

- Equipment debugging and manual sequencing

- Educational pneumatic training rigs

- Non-powered machinery controls

- Safety override in automated systems

1. Ensure arrow direction matches airflow requirements

2. Use thread sealant on male ports (tapered threads not recommended)

3. Lubricate pivot point annually with ISO VG32 hydraulic oil

4. Maximum lateral force on lever: 8N

| Property | Property Value |

|---|---|

| sku | 3L110-06 |

| Position | 3-Port 2-Position |

| Port | PT1/8 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.