2. Three-position pneumatic valve offers three selectable mid-position functions;

3. Dual-head 2-position configuration features memory retention capability;

4. Specialized machining processes for internal bores achieve low frictional resistance, low activation pressure, and extended service life;

5. Oil-free lubrication required;

6. Compatible with manifold base integration for space-efficient installation;

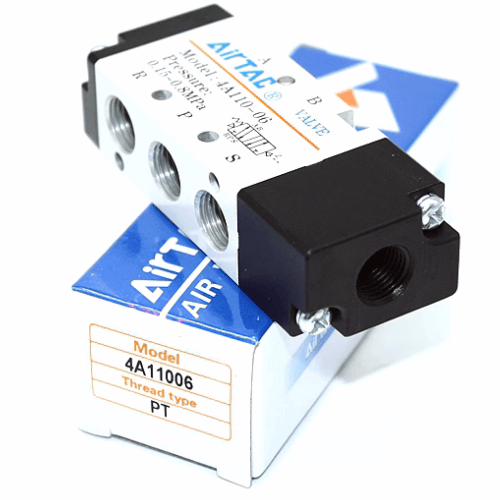

Category: Pneumatic Control Valves | Brand: AirTAC | Series: 4A100

AirTAC 4A100-04 (4A11006) Pneumatic Control Valve Technical Details

- Full model designation: 4A110-06 (4A11006)

- Valve type: 4-way/3-position (4A1 series)

- Control method: Air pilot operated (non-solenoid)

- Port configuration: P, A, B, R (ISO 5599-1 standard)

- Port size: 1/4" NPT (G1/4 optional)

- Operating pressure range: 0.2–0.8 MPa (29–116 PSI)

- Max flow capacity: 750 Nl/min (ANR)

- Pilot pressure requirement: ≥0.25 MPa

- Seal material: HNBR (Hydrogenated Nitrile)

- Temperature tolerance: -10℃ to 80℃ (14°F to 176°F)

- Body material: Aluminum alloy with hard anodizing

- Weight: 420g ±5% (without accessories)

- Dimensions: 58mm(W) × 42mm(H) × 102mm(L)

- Mounting pattern: ISO 4401-AC-04-4-A

- Response time: ≤0.2s (at 0.5 MPa)

Manual reset pneumatic directional valve designed for heavy-duty industrial applications requiring fail-safe position control. Features zero-power hold capability and IP67 protection rating, with shock/vibration resistance up to 10G. Requires 5μm filtered compressed air with lubricator (ISO 8573-1 class 4).

- Clamping fixture sequencing in CNC machining centers

- Emergency stop pneumatic circuits in press machinery

- Material handling system diverters

- Hydraulic system pilot stage controls

- Plastic injection molding machine safety gates

| Property | Property Value |

|---|---|

| sku | 4A11006 |

| Position | 5 Ports 2 Position |

| Port Size | PT1/8 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.