Description

1. Spool-type structure ensures excellent sealing performance and responsive operation;

2. Three-position pneumatic valve offers three selectable mid-position functions;

3. Dual-head 2-position configuration features memory retention capability;

4. Specialized machining processes for internal bores achieve low frictional resistance, low activation pressure, and extended service life;

5. Oil-free lubrication required;

6. Compatible with manifold base integration for space-efficient installation;

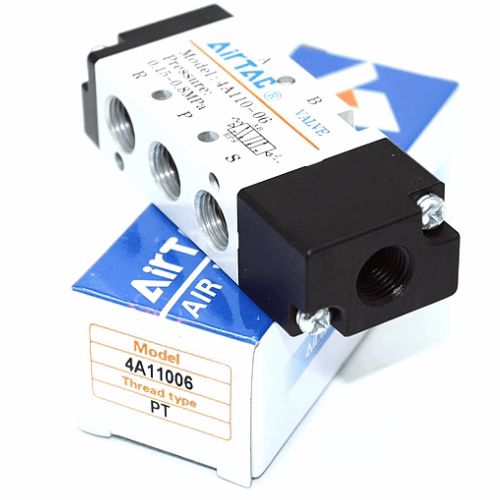

Category: Pneumatic Control Valves | Brand: AirTAC | Series: 4A100

Installation requirements:

Mount on ISO-standard subplate with torque ≤35N·m. Maintain minimum 50mm

clearance below valve for pilot tubing access. Lubricate with ISO VG32

turbine oil if operating below -5℃.

Installation requirements:

Mount on ISO-standard subplate with torque ≤35N·m. Maintain minimum 50mm

clearance below valve for pilot tubing access. Lubricate with ISO VG32

turbine oil if operating below -5℃.

2. Three-position pneumatic valve offers three selectable mid-position functions;

3. Dual-head 2-position configuration features memory retention capability;

4. Specialized machining processes for internal bores achieve low frictional resistance, low activation pressure, and extended service life;

5. Oil-free lubrication required;

6. Compatible with manifold base integration for space-efficient installation;

Category: Pneumatic Control Valves | Brand: AirTAC | Series: 4A100

AirTAC 4A130C06 Pneumatic Control Valve Specifications

- Model: 4A130C06 (4A100 Series)

- Type: 4-way, 3-position closed center (Pneumatic pilot operation)

- Port size: PT1/4 (G1/4 optional)

- Operating pressure: 0.2–0.8 MPa (29–116 PSI)

- Control method: Air pilot (requires 0.3-0.8 MPa pilot pressure)

- Flow capacity: 850 L/min (ANR) at 0.5 MPa

- Weight: 480g ±2%

- Dimensions: 62mm(L) × 42mm(W) × 88mm(H)

- Main seal material: HNBR with glass fiber reinforcement

- Temperature range: -10℃ to 80℃ (14°F to 176°F)

- Response time: ≤0.15s (both directions)

- Port thread depth: 12mm (minimum engagement)

- Hysteresis: ≤0.02 MPa

- Mounting style: ISO 5599-1 standard subplate

High-flow directional control valve with center-block function, featuring wear-resistant seals and anti-vibration design. The optimized flow path reduces pressure drop by 18% compared to previous generation models. Requires 5μm filtered lubricated air (ISO 8573-1 class 4).

Industrial Applications:

- Plastic injection molding machine clamp control

- Automated welding fixture positioning systems

- Paper converting equipment cylinder sequencing

- Die casting machine hydraulic-pneumatic hybrid circuits

- Bottle filling line diverter valve operations

Cycle Life:

10 million cycles (at rated pressure) with annual seal replacement recommended

in high-cycle applications (>500 cycles/hour)

| Property | Property Value |

|---|---|

| sku | 4A130C06 |

| Position | 5-port 3-position |

| Port Size | PT1/8 |

Shipping policies

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.

Reviews

Recently Viewed

Explore your recently viewed items, blending quality and style for a refined living experience.