2、3-position pneumatic valves offer three selectable center position configurations;

3、Double pneumatic pilot 2-position valves feature memory retention capability;

4、Precision-honed internal bore minimizes friction resistance, enables low pilot pressure activation, and guarantees extended service life;

5、Maintenance-free operation requiring no lubrication;

6、Manifold base compatibility for space-efficient system integration;

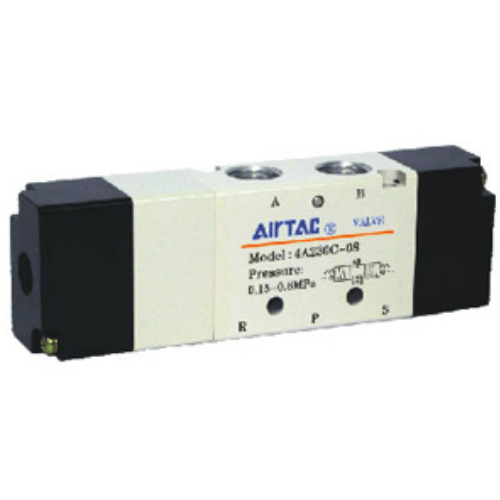

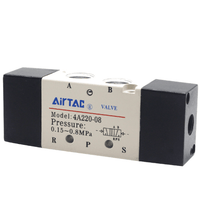

Category: Pneumatic Valves , Brand: AIRTAC , Series: 4A200

AirTAC 4A200 Series Pneumatic Valve 4A22006 Technical Details

- Model: 4A22006 (4A200 series)

- Valve type: 5/2-way monostable (single solenoid)

- Port configuration: 5 ports (P, A, B, EA, EB) / 2 positions

- Port size: PT1/4 (G1/4 optional)

- Operating pressure range: 0.15–1.0 MPa (21.7–145 psi)

- Voltage variants: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Weight: 320g ±5% (including coil)

- Dimensions: 56mm(L) × 45mm(W) × 75mm(H)

- Flow capacity: 850 l/min (Cv=1.2) at 0.5 MPa

- Seal materials: Main seal - HNBR, secondary seals - FKM

- Temperature tolerance: -10℃ to 80℃ (non-freezing)

- Power consumption: 2.8W (DC), 3.5VA (AC)

- Response time: ≤15ms (energize), ≤20ms (de-energize)

- Protection class: IP67 (coil), IP40 (valve body)

- Port thread depth: 12mm (minimum engagement)

High-flow directional control valve with pilot-assisted actuation, featuring optimized flow paths for reduced pressure drop. The aluminum alloy body with hard anodized treatment ensures durability in humid environments. Designed for systems requiring rapid cycling (up to 5Hz) and medium-duty pneumatic applications. Requires ISO 8573-1:2010 Class 3 compressed air (max 5mg/m³ oil content).

- Clamping mechanisms in CNC machining centers

- Actuator control for automated assembly lines

- Pneumatic cylinder sequencing in packaging machinery

- Material handling systems (conveyor diverters)

- Plastic injection molding machine ejectors

| Property | Property Value |

|---|---|

| sku | 4A22006 |

| Position | 5 Ports 2 Position |

| Port Size | PT1/4 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.