2. 3-position pneumatic valve offers three selectable center position configurations;

3. Double solenoid control for 2-position valve with latching function maintains position memory;

4. Precisely machined internal bore with specialized surface treatment delivers reduced friction resistance, lower actuation pressure, and extended service life;

5. Maintenance-free operation without lubrication requirement;

6. Modular design with base manifold compatibility optimizes space utilization;

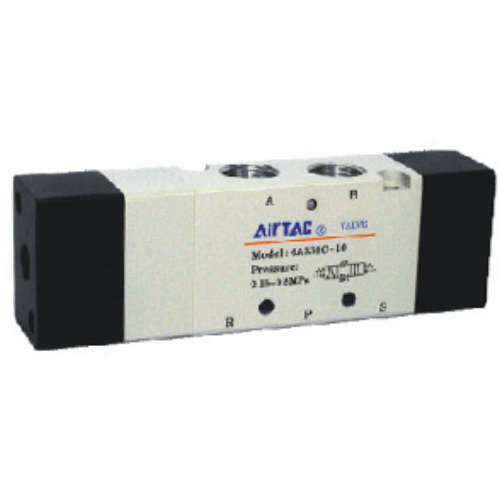

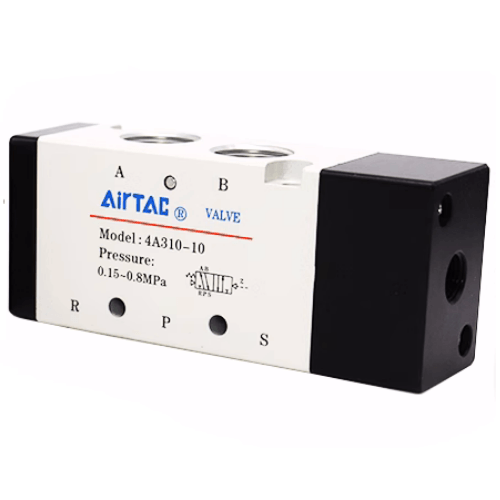

Category: Pneumatic Valves, Brand: AirTAC, Series: 4A300

AirTAC 4A300 Series 4A31010 Pneumatic Valve Specifications

- Model: 4A31010 (4A300 series)

- Type: 5/2-way single solenoid control (double pilot)

- Port size: G1/8 (ISO228/1 standard)

- Thread type: Internal parallel (NPT optional)

- Operating pressure: 0.1–1.0 MPa (14.5–145 PSI)

- Max flow rate: 750 L/min (ANR)

- Voltage options: DC12V/24V, AC110V/220V (±10%)

- Coil insulation class: Class F (155℃)

- Weight: 320g ±5% (including coil)

- Dimensions: 55mm(L) × 40mm(W) × 80mm(H)

- Seal material: FKM fluorocarbon rubber

- Temperature range: -10℃ to 80℃ (non-freezing)

- Power consumption: 2.5W (DC), 4.5VA (AC)

- Response time: ≤15ms (at 0.5MPa)

- Protection rating: IP67 (coil)/IP40 (valve body)

- Port alignment: ISO 5599/1 standard

High-flow pneumatic directional valve with manual override, featuring aluminum alloy body with hard anodized finish for corrosion resistance. Designed for bi-directional cylinder control with position memory function. Includes LED status indicator and surge protection circuit. Requires 5μm filtered lubricated air (ISO 8573-1 class 4).

- Automated assembly line clamping systems

- Plastic injection molding machine actuators

- Food processing pneumatic circuits (FDA-compliant versions available)

- CNC machine tool chuck controls

- Automotive welding robot end effectors

| Property | Property Value |

|---|---|

| sku | 4A31010 |

| Position | 5 Ports 2 Position |

| Port Size | PT3/8 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.