Description

4V100 Solenoid Valve Technical Specifications

1. Pilot operation: Selectable internal pilot or external pilot configuration;

2. Spool-type structure ensures excellent sealing performance and rapid response;

3. Three-position variants offer three distinct center-position functions;

4. Double solenoid 5/2-way configuration features latching (memory) function;

5. Special bore machining process minimizes friction resistance, achieves low actuation pressure (0.15MPa), and extends service life;

6. Lubrication-free operation;

7. Integrable with manifold bases for space-optimized valve arrangements;

8. Manual override provided for simplified installation and commissioning;

9. Multiple standard voltage options available (AC/DC).

Category: Solenoid Valves | Brand: AIRTAC | Series: 4V100

Installation guidelines:

Installation guidelines:

1. Mount in vibration-free area using M4 mounting screws (torque ≤1.2N·m)

2. Maintain ambient temperature below 60℃ with 30mm clearance from heat sources

3. Use locknuts (included) for port connections - do not overtighten

4. Perform monthly manual cycling for systems with infrequent operation

Compatibility note:

Compatibility note:

Not suitable for:

- Corrosive gases (CO2, NH3)

- Pulse frequencies exceeding 5Hz

- Continuous duty cycles over 90% (use tandem solenoid version)

1. Pilot operation: Selectable internal pilot or external pilot configuration;

2. Spool-type structure ensures excellent sealing performance and rapid response;

3. Three-position variants offer three distinct center-position functions;

4. Double solenoid 5/2-way configuration features latching (memory) function;

5. Special bore machining process minimizes friction resistance, achieves low actuation pressure (0.15MPa), and extends service life;

6. Lubrication-free operation;

7. Integrable with manifold bases for space-optimized valve arrangements;

8. Manual override provided for simplified installation and commissioning;

9. Multiple standard voltage options available (AC/DC).

Category: Solenoid Valves | Brand: AIRTAC | Series: 4V100

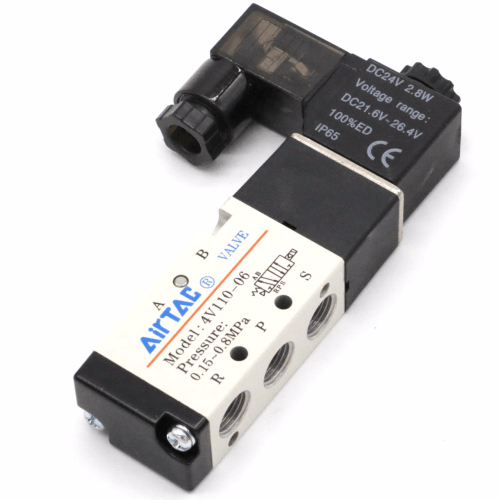

AirTAC 4V130C-06B-W Solenoid Valve Specifications

- Model: 4V130C-06B-W (Full designation: 4V100 series variant)

- Type: 5/2-way single solenoid spring return

- Port size: PT3/8 (G3/8 ISO standard)

- Thread type: BSPP (Parallel thread with O-ring seal)

- Operating pressure: 0.15–1.0 MPa (21.7–145 PSI)

- Voltage options:

- DC: 12V, 24V

- AC: 110V 50/60Hz, 220V 50Hz

- Flow capacity: 850 L/min (Cv=1.3 at 0.5MPa)

- Response time: ≤25ms (at rated voltage)

- Weight: 480g ±3% (with bracket)

- Dimensions: 62mm(L) × 50mm(W) × 80mm(H) (excluding ports)

- Seal material: HNBR rubber (Hydrogenated Nitrile for oil resistance)

- Temperature range: -10℃ to 80℃ (non-freezing)

- Power consumption: 2.2W (AC), 2.6W (DC)

- Protection rating: IP67 (dust-tight & temporary immersion)

- Manual override: Yes (integrated push-button actuator)

- Port orientation: Horizontal flow path design

High-flow directional control valve with rugged aluminum alloy body, designed for industrial automation requiring bi-directional actuation. Features shock-resistant coil housing and anti-vibration mounting points. Requires ISO 8573-1 class 3 compressed air (max 5mg/m³ oil content).

Typical Applications:

- Pneumatic cylinder sequencing in assembly lines

- Material handling systems (conveyor diverters)

- Plastic injection molding machine controls

- Automotive tire mounting equipment

- Industrial vacuum pump switching

1. Mount in vibration-free area using M4 mounting screws (torque ≤1.2N·m)

2. Maintain ambient temperature below 60℃ with 30mm clearance from heat sources

3. Use locknuts (included) for port connections - do not overtighten

4. Perform monthly manual cycling for systems with infrequent operation

Not suitable for:

- Corrosive gases (CO2, NH3)

- Pulse frequencies exceeding 5Hz

- Continuous duty cycles over 90% (use tandem solenoid version)

| Property | Property Value |

|---|---|

| sku | 4V130C06B-W |

| Position | 5-port 3-position |

| Port Size | PT1/8 |

| Standard Voltage | DC24V |

Shipping policies

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.

Reviews

Recently Viewed

Explore your recently viewed items, blending quality and style for a refined living experience.