1. Pilot operation: Selectable internal pilot or external pilot configuration;

2. Spool-type structure ensures excellent sealing performance and rapid response;

3. Three-position variants offer three distinct center-position functions;

4. Double solenoid 5/2-way configuration features latching (memory) function;

5. Special bore machining process minimizes friction resistance, achieves low actuation pressure (0.15MPa), and extends service life;

6. Lubrication-free operation;

7. Integrable with manifold bases for space-optimized valve arrangements;

8. Manual override provided for simplified installation and commissioning;

9. Multiple standard voltage options available (AC/DC).

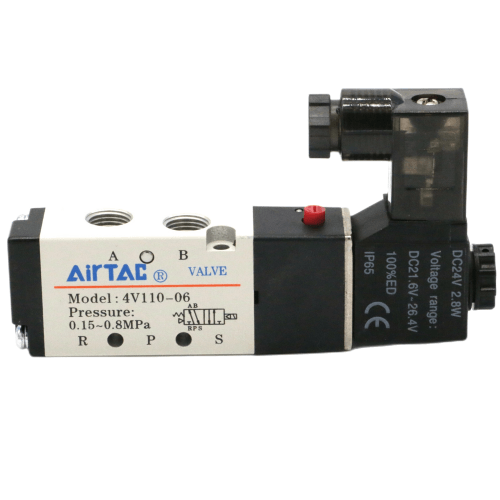

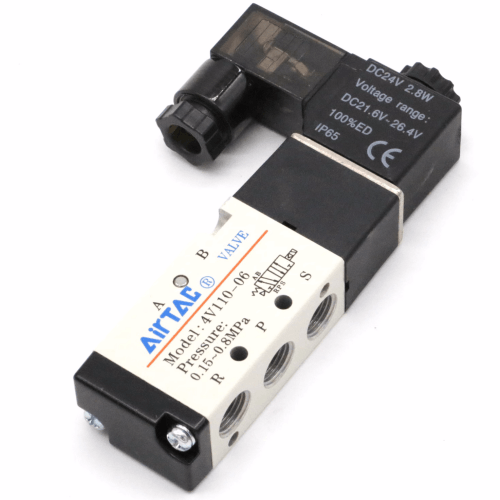

Category: Solenoid Valves | Brand: AIRTAC | Series: 4V100

AirTAC 4V130C06BI-W Solenoid Valve Specifications

- Model: 4V130C06BI-W

- Series: 4V100 (High Flow)

- Type: 5/2-way single solenoid, spring return

- Port size: PT1/4 (G1/4 optional)

- Operating pressure: 0.1–1.0 MPa

- Voltage options: DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Power consumption: 2.2W (DC), 3.5VA (AC)

- Max flow rate: 750 L/min (ANR)

- Response time: ≤15ms (exhaust to port A)

- Seal material: NBR (Nitrile), optional FKM

- Valve body material: Aluminum alloy (anodized)

- Temperature range: -5℃ to 60℃ (with anti-freeze measures below 0℃)

- Protection rating: IP67 (coil), IP40 (valve body)

- Weight: 480g ±5% (including connector)

- Dimensions: 50mm(W) × 45mm(H) × 90mm(L)

- Port thread depth: 12mm (minimum engagement)

- Expected lifespan: 50 million cycles (at no-load condition)

A high-flow directional control valve optimized for industrial automation systems. Features dual-pressure operation capability and surge-protected coils. The BI-W suffix indicates brass core construction with manual override and reinforced coil insulation. Requires 5μm filtered air (ISO 8573-1:2010 Class 4) with oil mist lubrication recommended.

- Pneumatic cylinder sequencing in assembly lines

- Material handling systems (e.g., conveyor diverters)

- Medical equipment sterilization chambers

- Packaging machine clamp control

- Semiconductor wafer handling robots

1. Mount in vibration <5m/s² using M5 mounting screws (max torque 1.2N·m)

2. Maintain ambient humidity below 85% RH (non-condensing)

3. For horizontal piping: Install exhaust port downward to prevent condensate ingress

4. Use shielded cable (min. 0.5mm²) for electrical connections

| Property | Property Value |

|---|---|

| sku | 4V130C06BI-W |

| Position | 5-port 3-position |

| Port Size | PT1/8 |

| Standard Voltage | DC24V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.