2、Terminal-type electrical connection with concentrated internal pilot exhaust, suitable for pollution-free workplaces requiring special environmental conditions;

3、Spool-type structure ensures excellent sealing performance and rapid response; multiple standard voltage ratings available;

4、3-position solenoid valves offer three center function options; double solenoid 2-position valves feature memory function;

5、Precision-machined inner bore minimizes friction resistance, enables low actuation pressure, and extends service life;

6、Compatible with modular valve banks for space-saving installation; integrated manual override facilitates commissioning and maintenance.

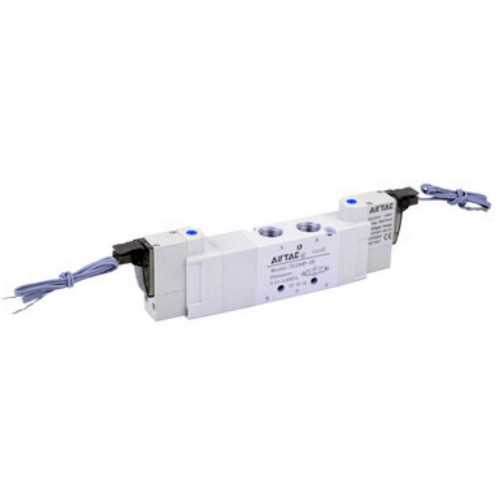

Category: Solenoid Valves , Brand: AIRTAC , Series: 5V

AirTAC 5V11006B200 Solenoid Valve Specifications

- Model: 5V11006B200

- Type: 5/2-way single solenoid (monostable)

- Port size: PT1/4 (G1/4 optional)

- Operating pressure: 0.15–0.8 MPa (21.7–116 psi)

- Voltage options: DC12V, DC24V, AC110V, AC220V (±10% tolerance)

- Weight: 230g ±5g (with connector)

- Dimensions: 52mm(L) × 42mm(W) × 75mm(H)

- Flow coefficient (Cv): 1.2

- Seal material: Heat-resistant NBR (Nitrile) with PTFE coating

- Temperature range: -5℃ to 80℃ (with intermittent peaks up to 120℃ for ≤10 mins)

- Power consumption: 2.2W (DC), 3.5VA (AC)

- Response time: ≤25ms (energize), ≤15ms (de-energize)

- Protection rating: IP67 (dust/water resistant)

- Housing material: Reinforced PBT with corrosion-resistant plating

High-flow directional control valve featuring dual-pressure operation capability and manual override function. The 5V11006B200 utilizes a spool-type design with precision-machined stainless steel guide sleeves for reduced friction. Its optimized magnetic circuit ensures stable performance under voltage fluctuations. Compatible with ISO 15407-1 standards, it requires 5μm filtered lubricated air (ISO 8573-1 class 4).

- Automated assembly line clamping systems

- Textile machinery cylinder control

- Plastic injection molding ejectors

- CNC tool changers

- Beverage filling station actuators

- Railway brake test benches

1. Mount in vibration-free locations using M4 mounting screws (max torque 1.2N·m)

2. Maintain ≥15mm clearance below exhaust ports for proper venting

3. Use shielded cables for electrical connections in high EMI environments

4. Lubricate every 5 million cycles using ISO VG32 turbine oil

| Property | Property Value |

|---|---|

| sku | 5V11006B200 |

| Position | 5 Ports 2 Position |

| Port Size | PT1/8 |

| Standard Voltage | DC24V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.