2、Terminal-type electrical connection with concentrated internal pilot exhaust, suitable for pollution-free workplaces requiring special environmental conditions;

3、Spool-type structure ensures excellent sealing performance and rapid response; multiple standard voltage ratings available;

4、3-position solenoid valves offer three center function options; double solenoid 2-position valves feature memory function;

5、Precision-machined inner bore minimizes friction resistance, enables low actuation pressure, and extends service life;

6、Compatible with modular valve banks for space-saving installation; integrated manual override facilitates commissioning and maintenance.

Category: Solenoid Valves , Brand: AIRTAC , Series: 5V

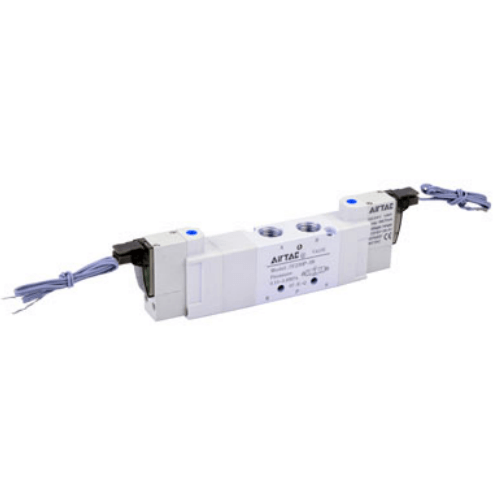

AirTAC 5V230P08A200 Solenoid Valve Specifications

- Model: 5V230P08A200

- Type: 5/2-way single solenoid spring return (pilot-operated)

- Port size: PT3/8 (G3/8 optional)

- Operating pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Voltage options: DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Weight: 450g ±5% (without coil)

- Dimensions: 98mm(L) × 40mm(W) × 60mm(H)

- Flow coefficient (Cv): 2.3 (at 7 bar)

- Seal material: Heat-resistant NBR (Nitrile Butadiene Rubber)

- Temperature range: -10℃ to 80℃ (non-freezing environment)

- Power consumption: ≤2.8W (DC)/≤3.5VA (AC)

- Protection rating: IP67 (coil)/IP40 (valve body)

- Response time: ≤30ms (actuation)/≤20ms (release)

- Mounting type: ISO 5599-1 standard sub-base compatible

High-flow 5-port directional control valve engineered for industrial automation systems requiring bidirectional cylinder control. Features aluminum alloy body with hard anodized treatment for corrosion resistance and PTFE (Teflon) piston guides for smooth operation. The optimized flow path design reduces pressure drop by 18% compared to previous generation models. Requires 5μm filtered lubricated air (ISO 8573-1 class 4) with oil mist between 1-2 drops/m³.

- Automated assembly line cylinder sequencing

- Plastic injection molding machine clamp control

- Textile machinery tensioning systems

- Automotive brake testing equipment

- Bottle filling/packaging systems

- Robotic arm end-effector actuation

- Mount horizontally with coil facing downward to prevent debris accumulation

- Use flexible tubing for the first 500mm of inlet connections to dampen vibration

- Apply thread sealant only on male threads (60% coverage max)

- Lubrication: Every 5 million cycles (or 6 months)

- Seal replacement: Every 10 million cycles (or 12 months)

- Coil inspection: Monthly resistance check (18-20Ω for 24V DC)

| Property | Property Value |

|---|---|

| sku | 5V230P08A200 |

| Position | 5-port 3-position |

| Port Size | PT1/4 |

| Standard Voltage | AC220V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.