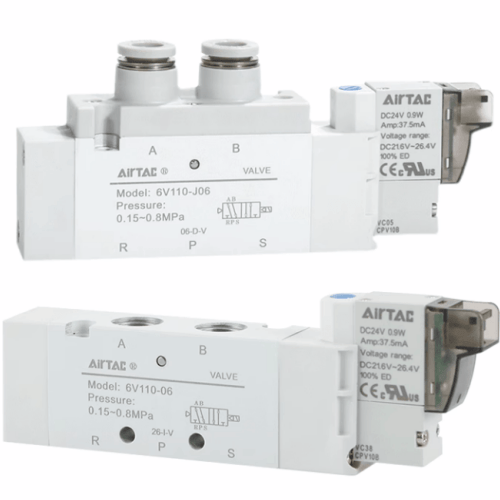

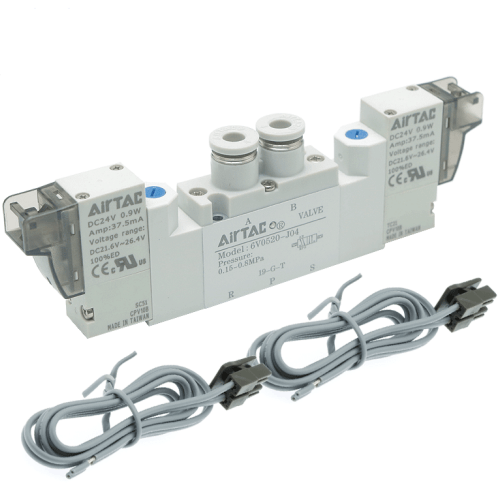

2、Internal venting structure collects pilot air for centralized exhaust through R/S ports;

3、High-pressure die-cast aluminum alloy body features precision-machined inner bore for optimized flow path geometry and enhanced flow capacity;

4、Available in threaded and quick-insertion port types, compatible with base-mounted valve manifolds for space-efficient installation.

Category: Solenoid Valves | Brand: AIRTC | Series: 6V

AirTAC 6V130PM5A200 Solenoid Valve Technical Details

- Model: 6V130PM5A200

- Type: 5/3-way closed center (pilot-operated)

- Port size: PT1/4 (G1/4 equivalent)

- Operating pressure: 0.1–1.0 MPa

- Voltage options: DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Flow capacity: 1300 L/min (ANR)

- Response time: ≤15ms (energize), ≤20ms (de-energize)

- Weight: 450g ±5% (with connectors)

- Dimensions: 120mm(L) × 52mm(W) × 45mm(H)

- Seal material: Heat-resistant NBR (Nitrile)

- Temperature range: -10℃ to 80℃ (non-freezing)

- Power consumption: ≤3.5W (DC), ≤4.5VA (AC)

- Protection rating: IP67 (dust/water resistant)

- Port thread depth: 12mm (internal)

- Coil insulation class: Class F (155℃)

High-flow proportional control valve with center-block function, featuring optimized spool geometry for smooth actuation. The aluminum alloy body with hard anodizing resists chemical corrosion and mechanical wear. Integrated surge suppression protects coil durability. Requires ISO 8573-1:2010 Class 3 compressed air (max 5μm particle size).

- Pneumatic cylinder sequencing in assembly lines

- Die-casting machine clamping controls

- Automotive brake testing systems

- Palletizing robot end-effectors

- Plastic injection molding machines

| Property | Property Value |

|---|---|

| sku | 6V130PM5A200 |

| Port Size | M5 |

| Standard Voltage | AC220V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.