2. Internal exhaust structure collects pilot gas and discharges centrally through R/S ports;

3. Aluminum alloy die-casting body with optimized flow path design enhances flow capacity;

4. Available in threaded or quick-connect versions, compatible with manifold base integration for space-saving installation.

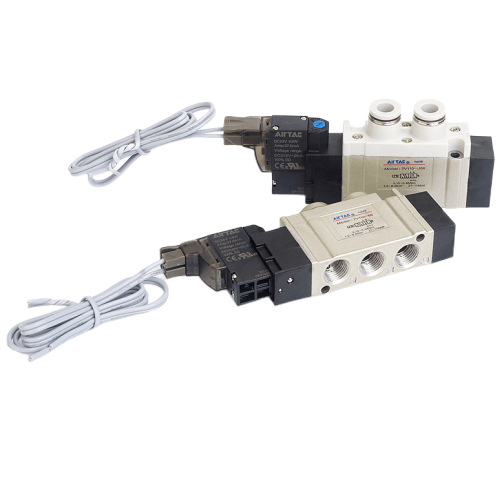

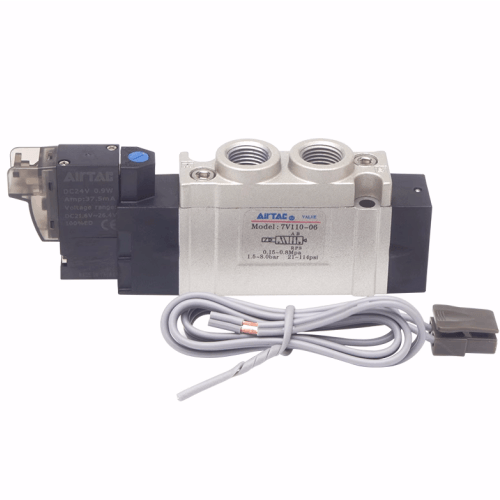

Category: Solenoid Valves, Brand: Airtac, Series: 7V

AirTAC 7V0510J04B200 Solenoid Valve Technical Details

- Model Code: 7V0510J04B200

- Valve Type: 5/2-way single solenoid (monostable)

- Port Configuration: 5 ports, 2 positions

- Port Thread: PT1/4 (G1/4 optional)

- Operating Pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Voltage Variants: DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Coil Insulation: Class F (155℃)

- Flow Capacity: 850 l/min (Cv=1.3 at 0.5MPa)

- Response Time: ≤15ms (energize), ≤20ms (de-energize)

- Seal Material: HNBR (Hydrogenated Nitrile) for improved oil resistance

- Ambient Temp Range: -10℃ to 60℃ (14℉ to 140℉)

- Fluid Temp Range: 0℃ to 60℃ (with dew point -25℃ below ambient)

- Protection Class: IP67 (dust-tight, temporary immersion)

- Electrical Connection: DIN43650 Form A (standard)

- Weight: 320g ±5% (without fittings)

- Dimensions: 56mm(L) × 45mm(W) × 75mm(H)

High-flow proportional solenoid valve with position feedback capability, featuring dual-pressure operation and zero-pressure differential start. The brass body with hard anodized aluminum core ensures durability in humid environments. Requires ISO 8573-1:2010 Class 3 compressed air (max 5mg/m³ oil content).

- Pneumatic cylinder sequencing in automated assembly lines

- Dual-pressure systems for injection molding machines

- Material handling equipment with position feedback requirements

- Cleanroom-compatible production systems (low particle emission)

- Bidirectional actuator control in packaging machinery

- Vertical installation preferred (±15° tolerance)

- Vibration resistance: 10–55Hz, 1.5mm amplitude max

- Electromagnetic compatibility: 1500V surge protection

- Minimum 12mm clearance for coil replacement

| Property | Property Value |

|---|---|

| sku | 7V0510J04B200 |

| Port Size | PT 1/2 |

| Standard Voltage | DC24V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.