2. Internal exhaust structure collects pilot gas and discharges centrally through R/S ports;

3. Aluminum alloy die-casting body with optimized flow path design enhances flow capacity;

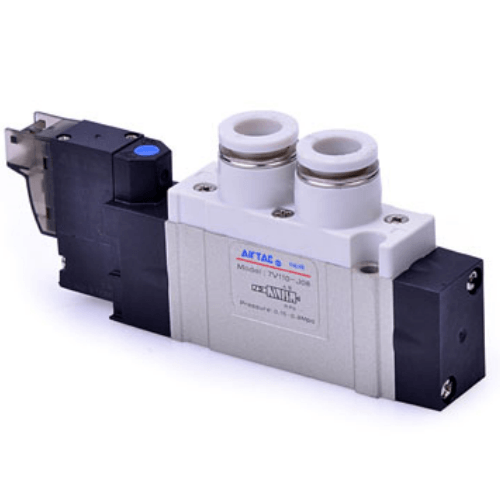

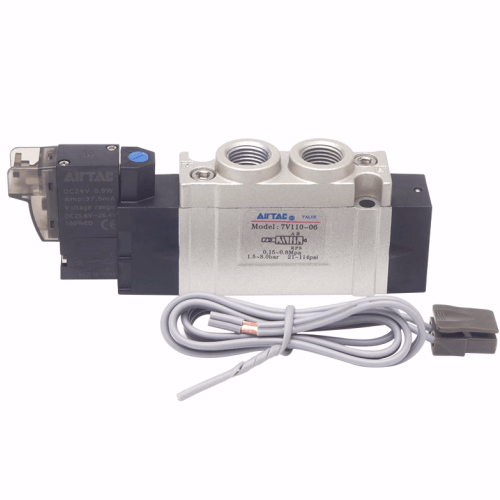

4. Available in threaded or quick-connect versions, compatible with manifold base integration for space-saving installation.

Category: Solenoid Valves, Brand: Airtac, Series: 7V

AirTAC 7V0520M5C200 Solenoid Valve Specifications

- Model: 7V0520M5C200

- Type: 5/2-way monostable (single solenoid)

- Port size: PT1/8 (M5x0.8 threaded ports)

- Operating pressure: 0.1–0.9 MPa (14.5–130.5 PSI)

- Voltage: DC24V (±10% ripple)

- Coil power: 1.6W (Class F insulation)

- Response time: ≤15ms (at 0.5 MPa)

- Flow rate: 850 l/min (ANR, at 0.5 MPa)

- Seal material: Heat-resistant NBR (+90℃ peak)

- Ambient temperature: -5℃ to 60℃ (with anti-freeze measures)

- Weight: 310g ±5% (including coil)

- Dimensions: 70mm(L) × 40mm(W) × 85mm(H)

- Port configuration: 5 ports (P, A, B, EA, EB)

- Protection rating: IP67 (dust/water resistant)

- Service life: ≥10 million cycles (under rated conditions)

High-speed 5-port directional control valve with optimized flow path design for bidirectional cylinder control. Features dual exhaust ports (EA/EB) for rapid pressure release and a low-friction spool structure enabling 50% faster response than standard models. The aluminum alloy body with hard anodizing resists chemical corrosion in harsh environments.

- Robotic arm gripper positioning systems

- Plastic injection molding machine ejectors

- CNC tool changers with pneumatic clamps

- Bottle filling line diverters

- Textile machinery tension control

| Property | Property Value |

|---|---|

| sku | 7V0520M5C200 |

| Port Size | M5 |

| Standard Voltage | AC 110V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.