2. Internal exhaust structure collects pilot gas and discharges centrally through R/S ports;

3. Aluminum alloy die-casting body with optimized flow path design enhances flow capacity;

4. Available in threaded or quick-connect versions, compatible with manifold base integration for space-saving installation.

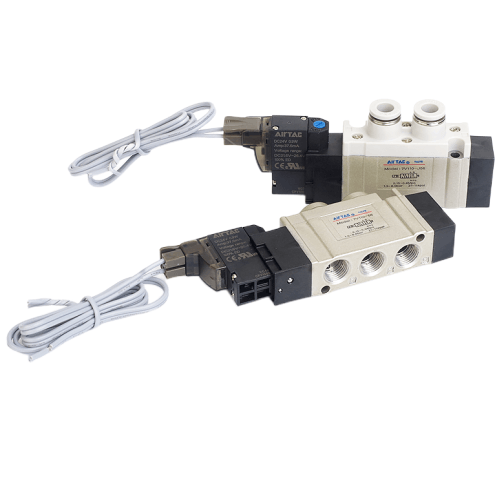

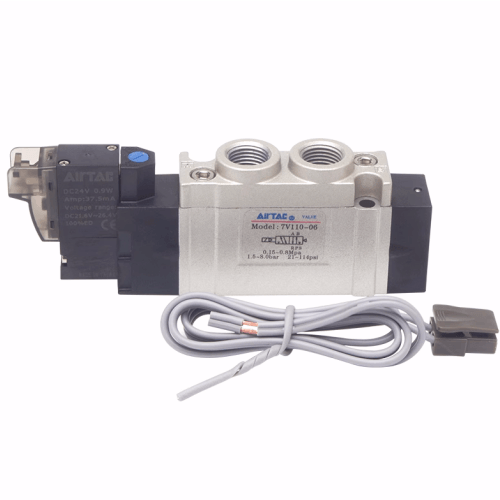

Category: Solenoid Valves, Brand: Airtac, Series: 7V

AirTAC 7V120J04F200 Solenoid Valve Technical Details

- Model Decoding: 7V(5-port 2-position) | 12(Φ12mm orifice) | 0J(Standard coil) | 04(PT1/4 port) | F200(Manual override + LED indicator)

- Valve Type: 5/2-way double solenoid (Bi-stable)

- Port Thread: G1/4 (BSPP) with ISO 228 standard

- Operating Pressure: 0.1–1.0 MPa (14.5–145 PSI)

- Flow Capacity: 750 l/min (Cv=1.2 at 0.5 MPa)

- Voltage Variations: DC12V/24V ±10%, AC110V/220V ±10% 50/60Hz

- Power Consumption: 3.8W (DC), 5.5VA (AC)

- Response Time: ≤20ms (Energized), ≤30ms (De-energized)

- Seal Material: HNBR with PTFE piston ring (-20℃ to 150℃)

- Body Material: Anodized aluminum alloy (A6063-T5)

- Protection Class: IP67 (Dustproof & waterproof)

- Weight: 450g ±3% (With connectors)

- Dimensions: 62mm(L) × 45mm(W) × 96mm(H)

- Port Spacing: 18mm between centers (Horizontal ports)

High-flow directional valve with dual coil memory function, featuring gold-plated terminals for stable conductivity. The integrated manual override allows mechanical actuation during maintenance. Optimized spool design reduces internal leakage to ≤30 ml/min at 0.5 MPa. Requires ISO 8573-1:2010 Class 3 compressed air (max 5μm particles, -20°C dew point).

- Palletizing robot end-effector controls

- Plastic injection molding machine clamp systems

- Automated warehouse stacker cylinders

- Lithium battery production line vacuum circuits

- Test bench pressure cycling systems

| Property | Property Value |

|---|---|

| sku | 7V120J04F200 |

| Port Size | PT 1/2 |

| Standard Voltage | DC12V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.