2. Internal exhaust structure collects pilot gas and discharges centrally through R/S ports;

3. Aluminum alloy die-casting body with optimized flow path design enhances flow capacity;

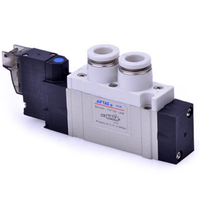

4. Available in threaded or quick-connect versions, compatible with manifold base integration for space-saving installation.

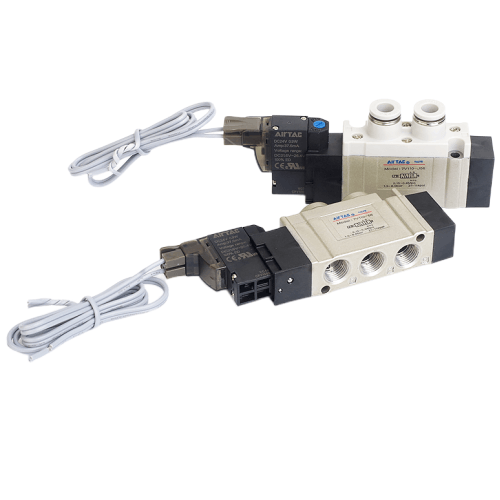

Category: Solenoid Valves, Brand: Airtac, Series: 7V

AirTAC 7V220J08B200 Solenoid Valve Technical Details

- Model: 7V220J08B200

- Type: 5/2-way single solenoid spring return

- Port size: PT1/4 (G1/4 equivalent)

- Operating pressure: 0.15–1.0 MPa (21.7–145 psi)

- Voltage options: DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Flow coefficient (Cv): 2.5

- Response time: ≤15ms (energize), ≤20ms (de-energize)

- Weight: 285g ±5g

- Dimensions: 57mm(L) × 43mm(W) × 78mm(H)

- Body material: Reinforced PBT resin with fiberglass

- Seal material: Heat-resistant NBR (optionally available in FKM)

- Temperature range: -10℃ to 80℃ (extended to 120℃ with FKM seals)

- Power consumption: 2.8W (DC24V), 3.5VA (AC)

- Protection rating: IP67 (dustproof and waterproof immersion up to 1m)

- Port thread depth: 10mm (minimum engagement required)

High-flow directional control valve featuring twin pressure balance structure for stable operation under fluctuating loads. The corrosion-resistant coil housing integrates surge protection and LED operation indicator. Requires 5μm filtered dry air with ISO 8573-1:2010 Class 3.4.3 air quality standard.

- Pneumatic cylinder sequencing in automated assembly lines

- Clamping/unclamping mechanisms in CNC machining centers

- Material handling systems with rapid cycling requirements

- Cleanroom-compatible production equipment (FKM seal version)

- Plastic injection molding machine air circuits

| Property | Property Value |

|---|---|

| sku | 7V220J08B200 |

| Port Size | PT1/4 |

| Standard Voltage | DC24V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.