2. Internal exhaust structure collects pilot gas and discharges centrally through R/S ports;

3. Aluminum alloy die-casting body with optimized flow path design enhances flow capacity;

4. Available in threaded or quick-connect versions, compatible with manifold base integration for space-saving installation.

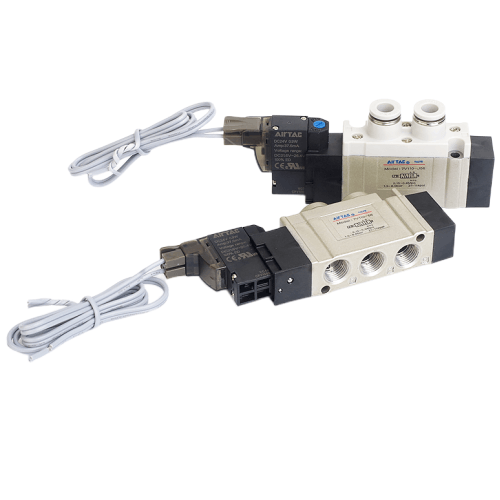

Category: Solenoid Valves, Brand: Airtac, Series: 7V

AirTAC 7V230E08A200 Solenoid Valve Technical Details

- Model: 7V230E08A200

- Type: 5/3-way closed center (triple position) with double solenoid

- Port size: G1/4 (ISO228/1 standard)

- Operating pressure range: 0.15–0.8 MPa (21.7–116 PSI)

- Voltage variants: DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Flow capacity: 1,100 Nl/min (Cv=1.8) @ 0.5 MPa

- Response time: ≤15ms (energize), ≤20ms (de-energize)

- Body material: Aluminum alloy (anodized surface)

- Seal material: Heat-resistant NBR (-20℃ to 80℃)

- Weight: 410g ±5% (excluding connectors)

- Dimensions: 76mm(L) × 54mm(W) × 92mm(H)

- Port thread depth: 12mm (full engagement recommended)

- Protection class: IP67 (dust-tight, protected against immersion)

- Max cycling rate: 5Hz (300 cycles/minute)

- Coil insulation class: Class F (155℃)

High-flow directional control valve with center-block function, engineered for complex pneumatic circuits requiring mid-position pressure locking. Features rapid response solenoids with overcurrent protection (125% rated current tolerance) and manual override capability. Requires ISO 8573-1:2010 Class 3 lubricated air (max 40mg/m³ oil content).

- Plastic injection molding machine clamp control

- Automated assembly line positioning systems

- Die-casting machine hydraulic-pneumatic interfaces

- Food processing equipment with CIP washdown requirements

- Semiconductor wafer handling robotics

| Property | Property Value |

|---|---|

| sku | 7V230E08A200 |

| Port Size | PT1/4 |

| Standard Voltage | AC220V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.