2. Enhanced structural integrity with threaded end covers for superior strength and maintenance accessibility;

3. Barrel interior features precision machining with hard anodized treatment for exceptional wear resistance and durability;

4. Specialized bidirectional sealing structure on piston ensures compact dimensions with integrated oil reservoir functionality;

5. Space-optimized compact design for efficient spatial utilization in installations;

6. Perimeter grooves for magnetic sensor switch mounting with tool-free installation convenience;

7. Multiple mounting accessory configurations available for flexible adaptation;

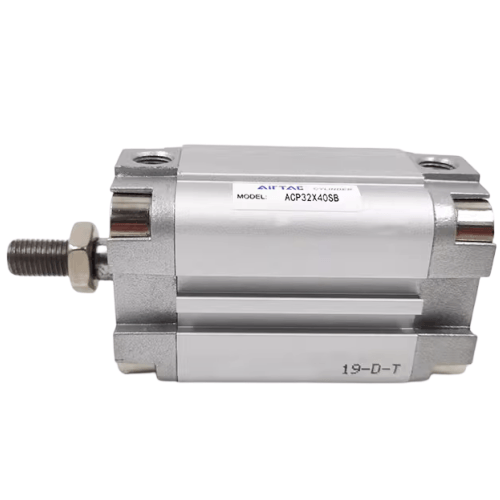

Category: Compact Cylinders | Brand: AirTAC | Series: ACP

AirTAC ACP Compact Cylinder ACP32X10SH Technical Details

- Model: ACP32X10SH (ISO 6432 compliant)

- Bore size: 32mm (±0.1mm tolerance)

- Stroke: 10mm (adjustable cushioning)

- Operating pressure: 0.05-1.0 MPa

- Piston speed: 50-800 mm/s (lubricated)

- Port size: M5x0.8 (standard) / NPT1/8 (optional)

- Cushioning type: Rubber buffer + adjustable shock absorber

- Mounting style: Basic type (axial foot mount available)

- Rod thread: M10x1.25 (ISO 12240-1)

- Material:

- Tube: Aluminum alloy (hard anodized)

- Piston rod: Chrome-plated steel (HRC 45-50)

- Seals: NBR (standard) / FKM (high temp option)

- Temperature range: -20℃ to 80℃ (extended to 120℃ with FKM seals)

- Weight: 1.2kg ±3% (excluding accessories)

- Dimensions:

- Length: 115mm (min. retracted length)

- Width: 42mm (max. cross-section)

- Height: 42mm (mounting surface to rod center)

- ISO protection class: IP67 (wipers included)

- Service life: 5,000km (50mm/s under S1 operation mode)

High-precision compact cylinder featuring dual cushioning system and multi-position mounting slots. The triple-lip wiper design ensures contamination resistance in harsh environments. Optional magnetic piston version (ACP32X10SH-M) available for position sensing. Lubricator-free design with pre-greased seals.

- Precision clamping in CNC tool changers

- Material positioning in semiconductor handlers

- Valve actuation in compact food processing lines

- Automated test equipment component cycling

- Robotic end-effector gripping mechanisms

- Relubrication interval: 5 million cycles (using ISO VG32 hydraulic oil)

- Wiper replacement: Every 2 years or 10,000 operating hours

- Piston rod inspection: Quarterly in high particulate environments

| Property | Property Value |

|---|---|

| sku | ACP32X10SH |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | S-Magnetic |

| Bore Diameter | <32 mm> |

| Stroke | <10mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.