2. Enhanced structural integrity with threaded end covers for superior strength and maintenance accessibility;

3. Barrel interior features precision machining with hard anodized treatment for exceptional wear resistance and durability;

4. Specialized bidirectional sealing structure on piston ensures compact dimensions with integrated oil reservoir functionality;

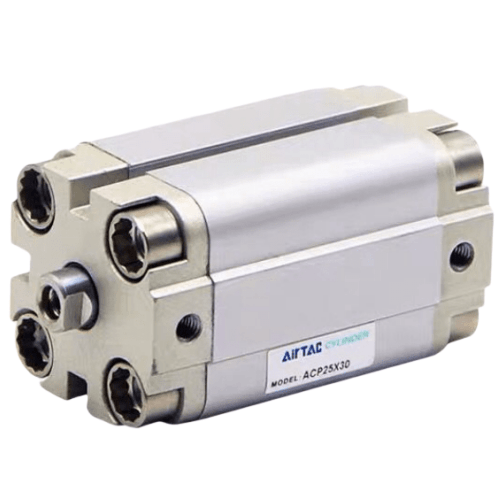

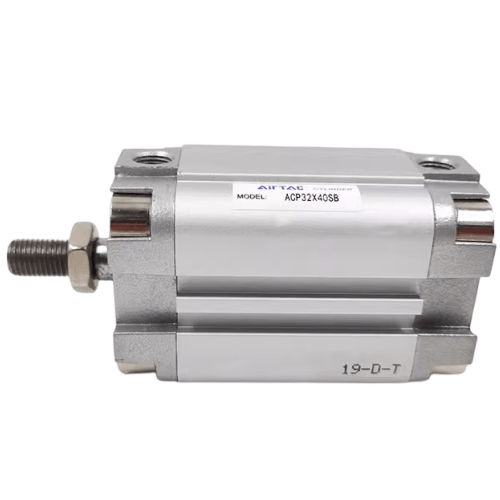

5. Space-optimized compact design for efficient spatial utilization in installations;

6. Perimeter grooves for magnetic sensor switch mounting with tool-free installation convenience;

7. Multiple mounting accessory configurations available for flexible adaptation;

Category: Compact Cylinders | Brand: AirTAC | Series: ACP

AirTAC ACP Compact Cylinder ACP63X300 Technical Specifications

- Model: ACP63X300

- Bore size: 63 mm

- Stroke: 300 mm

- Operating pressure: 0.15–0.8 MPa (21.7–116 psi)

- Ambient temperature: -20℃ to 80℃

- Cushion type: Adjustable pneumatic cushion

- Mounting style: Basic type (MF1) with multiple optional configurations

- Port size: M5x0.8 or 1/8 NPT (standard dual ports)

- Piston speed: 50–800 mm/s (with cushion)

- Material:

- Cylinder tube: Hard anodized aluminum alloy

- End covers: Die-cast aluminum

- Piston rod: Stainless steel (SUS304)

- Seal material: Nitrile rubber (NBR) standard (Polyurethane available for special orders)

- Weight: 2.3 kg (with rod, without accessories)

- Dimensions:

- Length: 478 mm (full extension)

- Width: 82 mm (including ports)

- Height: 82 mm (square body profile)

- ISO standard: Compliant with ISO 6432 (mounting dimensions)

The ACP63X300 compact cylinder combines high thrust force (1,960N at 0.6MPa) with space-saving design, featuring a 20% smaller cross-section than standard ISO cylinders. Its anti-rotation guide mechanism ensures precise linear motion, while the double-sealing piston design reduces air consumption by 15% compared to conventional models. Requires ISO VG32 or equivalent hydraulic oil lubrication for optimal performance.

- Automated clamping devices in CNC machining centers

- Vertical lifting mechanisms for packaging conveyors

- Precision press-fit operations in electronic assembly

- Material handling gates in food processing lines

- Positioning stages for laser cutting machines

- Allow 5mm minimum clearance for rod extension

- Horizontal mounting recommended for strokes >200mm

- Use adjustable mounting brackets (sold separately) for vibration-prone environments

- Install speed controllers (ASC-02 type) for strokes exceeding 150mm

- Relubricate every 500,000 cycles or 12 months

- Inspect rod seals every 2,000 operating hours in high-humidity environments

- Replace cushion seals when deceleration efficiency drops below 70%

| Property | Property Value |

|---|---|

| sku | ACP63X300 |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | Non-magnetic |

| Bore Diameter | 63mm |

| Stroke | 300mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.