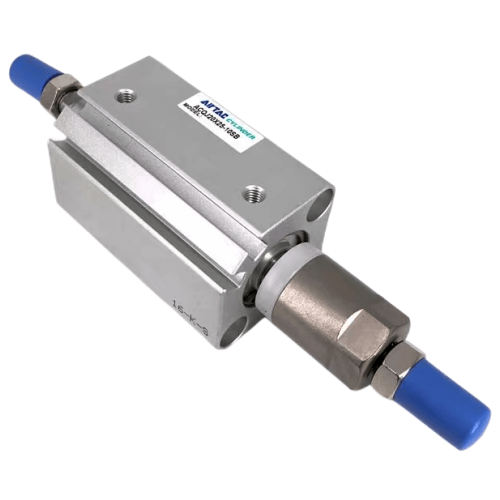

2. Features C-shaped retaining rings for cylinder body and end caps fixation, with piston-rod riveted connection ensuring compactness and structural reliability;

3. Precision-honed cylinder bore surface delivers wear-resistant and excellent durability;

4. Extended front-end guide distance enhances guidance precision;

5. Space-optimized design with compact profile maximizes installation space efficiency;

6. Pre-machined sensor slots along cylinder periphery facilitates straightforward sensor integration;

7. Multiple standardized mounting accessories available for flexible configuration;

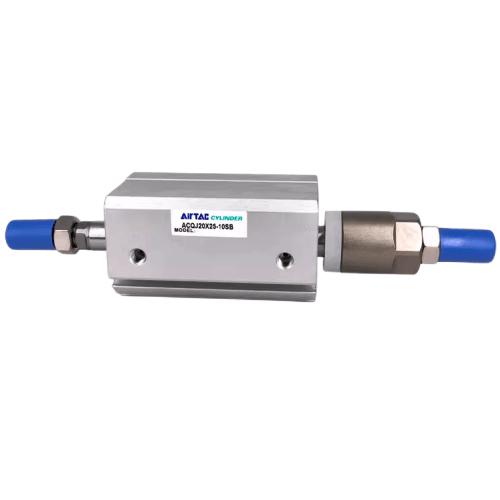

Category: Compact Cylinders | Brand: AIRTAC | Series: ACQJ125~160 Adjustable Compact Cylinder

AirTAC ACQJ140X175-50S Adjustable Compact Cylinder Specifications

- Series: ACQJ125~160 (Compact Adjustable Cushion Series)

- Model Breakdown:

- ACQJ140: Bore size 140mm

- 175: Stroke length 175mm

- 50S: Front/rear cushion adjusters + specific mounting variant

- Bore diameter: 140mm ±0.1mm

- Stroke tolerance: +2.0mm/-0mm

- Operating pressure: 0.05-1.0 MPa (0.5-10 bar)

- Ambient temperature: -20℃ to 80℃ (non-freezing conditions)

- Cushion type: External adjustable rubber bumper (10° rotation increments)

- Mounting style: Basic type (standard flange) with ISO 15552 mounting pattern

- Piston rod material: Hard chrome-plated carbon steel (S45C)

- Tube material: Anodized aluminum alloy (AL6063-T5)

- Seal material: NBR + PU combination seals

- Weight: 6.8 kg (dry, without accessories)

- Dimensions:

- Retracted length: 355mm (cylinder body: 175mm + stroke)

- Extended length: 530mm

- Width (square body): 162mm

- Height (mounting face to top): 158mm

- Lubrication: Pre-lubricated (ISO VG32 equivalent), maintenance-free for 5,000km stroke

Ultra-flat profile cylinder (height-to-bore ratio 1.13:1) with dual adjustable pneumatic cushions for precise end-position deceleration control. Features wear-resistant "Double O-ring + Wiper" triple sealing system and anti-rotation piston rod. Optional magnetic piston version (add "-M" suffix) for position sensing.

- Press machine ejection systems requiring controlled return speed

- Automated palletizing arms needing space-efficient actuators

- Plastic injection molding clamp mechanisms

- Heavy-duty conveyor gate actuators in logistics systems

- Automotive welding fixture positioning

1. Maintain 0.5mm minimum parallel alignment tolerance during mounting

2. Use M12x1.75 mounting bolts (Grade 8.8 or higher)

3. Cushion adjustment: Turn clockwise to soften, counterclockwise to harden

4. Lubricator required if air line contains particulate >5μm

| Property | Property Value |

|---|---|

| sku | ACQJ140X175-50S |

| Mounting Type | S-Magnetic |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | <50mm> |

| Magnet | PT3/8 |

| Bore Diameter | <140mm> |

| Stroke | 175mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.