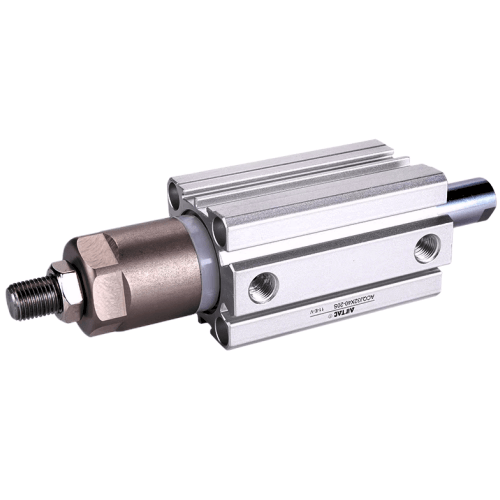

2. Features C-shaped retaining rings for cylinder body and end caps fixation, with piston-rod riveted connection ensuring compactness and structural reliability;

3. Precision-honed cylinder bore surface delivers wear-resistant and excellent durability;

4. Extended front-end guide distance enhances guidance precision;

5. Space-optimized design with compact profile maximizes installation space efficiency;

6. Pre-machined sensor slots along cylinder periphery facilitates straightforward sensor integration;

7. Multiple standardized mounting accessories available for flexible configuration;

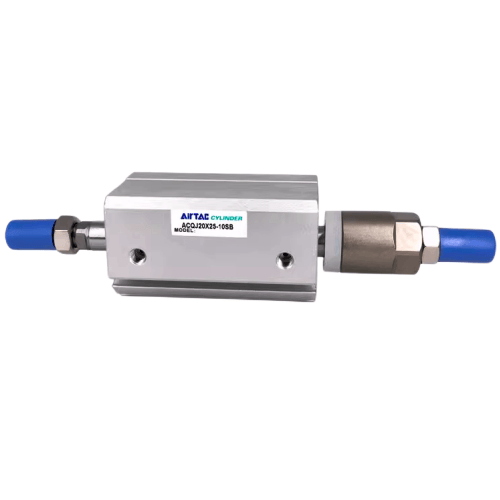

Category: Compact Cylinders | Brand: AIRTAC | Series: ACQJ125~160 Adjustable Compact Cylinder

AirTAC ACQJ160X200-75SB Adjustable Slim Cylinder Specifications

- Series: ACQJ125~160 (Standard adjustable thin-type cylinder)

- Model Code Breakdown:

- ACQJ: Series identifier

- 160: Bore size (mm)

- X200: Stroke length (mm)

- -75SB: 75mm adjustable cushion + SB (special buffer structure)

- Bore Size: 160mm (±0.5mm manufacturing tolerance)

- Stroke: 200mm (Max stroke for this model variant)

- Adjustable Cushion Range: 75mm (Mechanically adjustable at both ends)

- Operating Pressure: 0.05-1.0 MPa (1.5-145 PSI)

- Buffer Type: Air cushion with SB (Shock Absorbing Buffer) mechanism

- Port Size: G3/8 (Standard) / Optional NPT1/2

- Mounting: ISO/VDMA standard mounting patterns (MF1/MF2/MF4)

- Operating Temperature: -20℃ to 80℃ (Dry air required below 0℃)

- Piston Material: High-grade aluminum alloy with hard anodizing

- Rod Material: Chrome-plated steel (Cr equivalent ≥0.8μm)

- Seals: HNBR (Hydrogenated Nitrile) for high temperature resistance

- Weight: 9.8kg ±2% (Without accessories)

- Dimensions:

- Extended Length: 558mm (Cylinder length at full extension)

- Retracted Length: 358mm

- Body Width: 176mm (Including mounting flanges)

- Height: 160mm (Bore diameter equivalent)

- ISO Certification: Compliant with ISO 6431, VDMA 24562 standards

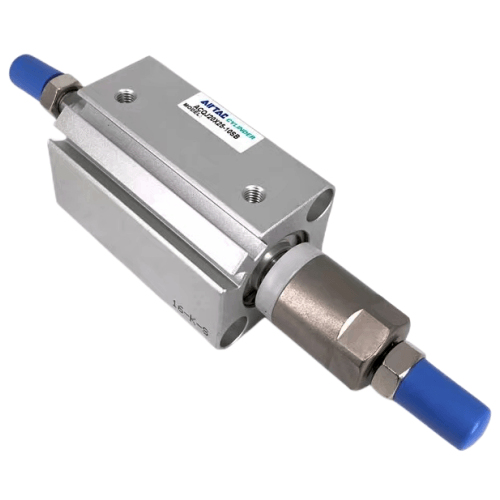

Ultra-slim profile cylinder (30% thinner than standard models) featuring dual adjustable pneumatic cushions with shock-absorbing buffer technology. The SB variant incorporates a multi-stage deceleration mechanism that reduces terminal impact by 60% compared to basic models. Precision machined guide grooves allow ±5° rotation adjustment during installation. Requires ISO 8573-1:2010 class 3-4-3 compressed air.

- High-speed press machines (800-1200 cycles/min)

- Automated palletizing systems with space constraints

- Plastic injection molding ejector mechanisms

- Precision glass handling in solar panel production

- Vertical CNC tool changers requiring slim actuators

- Align cylinder axis within 0.2mm/m deviation

- Apply Molykote G-5007 grease for -20℃ environments

- Maintain 50mm clearance behind cushion adjustment screws

- Use torque-controlled tightening (Mounting bolts: 35-40N·m)

| Property | Property Value |

|---|---|

| sku | ACQJ160X200-75SB |

| Mounting Type | S-Magnetic |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | 75mm |

| Magnet | PT3/8 |

| Bore Diameter | 160mm |

| Stroke | <200mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.