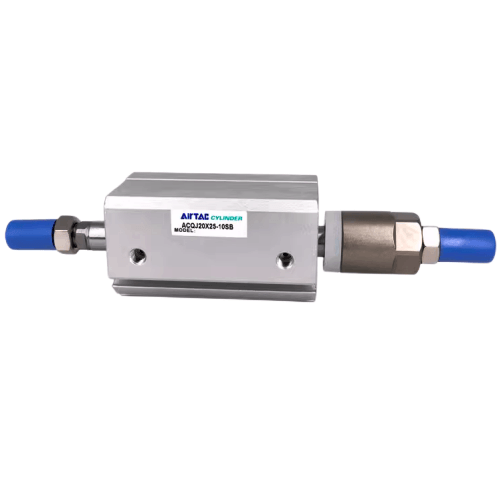

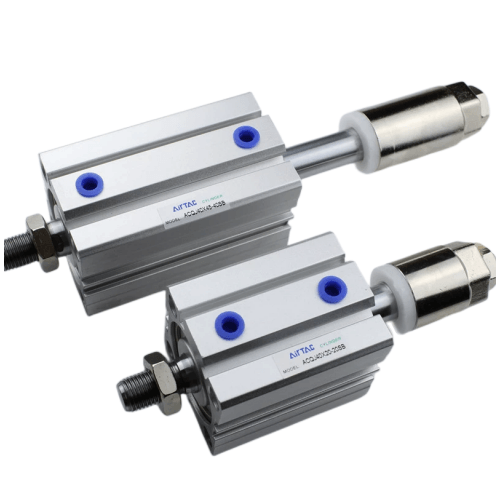

2. Features C-shaped retaining rings for cylinder body and end caps fixation, with piston-rod riveted connection ensuring compactness and structural reliability;

3. Precision-honed cylinder bore surface delivers wear-resistant and excellent durability;

4. Extended front-end guide distance enhances guidance precision;

5. Space-optimized design with compact profile maximizes installation space efficiency;

6. Pre-machined sensor slots along cylinder periphery facilitates straightforward sensor integration;

7. Multiple standardized mounting accessories available for flexible configuration;

Category: Compact Cylinders | Brand: AIRTAC | Series: ACQJ125~160 Adjustable Compact Cylinder

AirTAC ACQJ160X300-100S Adjustable Compact Cylinder Specifications

- Series: ACQJ125~160 (Adjustable Thin-Type Cylinder Series)

- Full model: ACQJ160X300-100S

- Bore size: 160mm

- Stroke: 300mm

- Adjustable cushioning: ±5% stroke adjustment range

- Operating pressure: 0.1~0.9 MPa

- Operating temperature: -20℃~80℃

- Piston speed: 50~800 mm/s

- Mounting type: Basic foot mounting (MF1 style)

- Rod end: External thread M45×1.5

- Cushion design: Air cushion with adjustable needle valve

- Seal material: NBR (Nitrile rubber) standard, optional FKM

- Body material: Aluminum alloy with hard anodized surface

- Weight: 8.2 kg (excluding accessories)

- Dimensions:

- Total length (L): 493mm (at mid-stroke)

- Body width (W): 180mm (mounting foot span)

- Height (H): 165mm (including rod end)

- Mounting hole spacing: 150×150mm

- Port size: G1/2 (ISO228 standard)

- Lubrication: Pre-lubricated (Oil-free operation possible)

- Protection class: IP65 (Dust-tight & protected against water jets)

Ultra-flat cylinder (height reduced by 25% vs standard models) with precision-adjustable air cushioning, designed for space-constrained industrial automation. Features wear-resistant chromium-plated piston rod and integrated mounting grooves for flexible installation. The 100S suffix indicates special high-tolerance machining for repetitive positioning applications.

- High-speed press machine ejection systems

- Automated palletizing robot end-effectors

- Plastic injection molding machine core-pulling

- Semiconductor wafer handling equipment

- Automotive welding fixture positioning

- Use with AirTAC 4V310-10 solenoid valve for ≤1.5m/s speed control

- Match with MSC-50 magnetic sensor for position feedback

- Combine with JSC-160 shock absorber for high-cycle applications

| Property | Property Value |

|---|---|

| sku | ACQJ160X300-100S |

| Mounting Type | S-Magnetic |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | 100mm |

| Magnet | PT3/8 |

| Bore Diameter | 160mm |

| Stroke | 300mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.