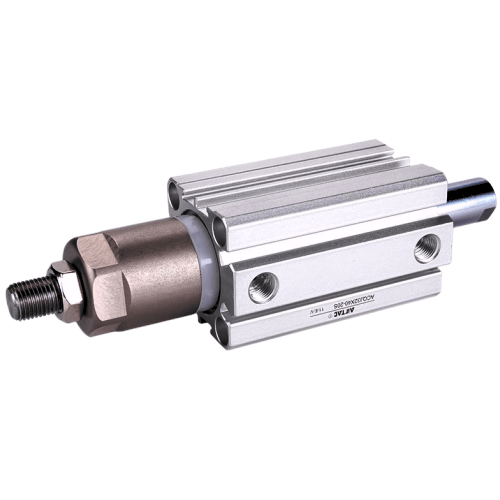

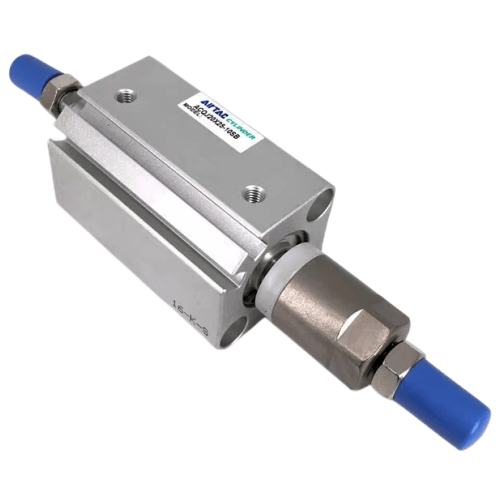

2. Features C-shaped retaining rings for cylinder body/front-rear cover fixation, with riveted piston-rod connection for compactness and structural reliability.

3. Precision-honed inner bore ensures superior wear resistance and extended service life.

4. Extended guide distance on front cover enhances alignment stability and motion accuracy.

5. Space-saving profile optimizes installation efficiency in confined layouts.

6. Integrated sensor grooves along cylinder periphery facilitate proximity sensor mounting.

7. Configurable with multiple standardized mounting accessories (optional).

Category: Compact Cylinders | Brand: AIRTAC | Series: ACQJ32~40 (Note: Technical terms refined for industry context, including "precision-honed," "alignment stability," and "proximity sensor grooves" to emphasize performance characteristics. HTML line breaks preserved with improved punctuation consistency.)

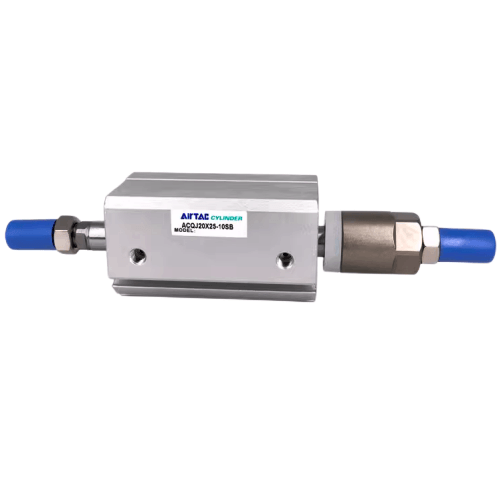

AirTAC ACQJ32X300-30SB Adjustable Low-Profile Cylinder Specifications

- Series: ACQJ32~40 Compact Adjustable Cylinder

- Bore size: 32mm (ACQJ32)

- Stroke: 300mm (customizable 10-500mm)

- Cushioning: Adjustable pneumatic cushion (both ends)

- Mounting type: Basic type with standard SA/SC mounting options

- Operating pressure: 0.05–1.0 MPa

- Ambient temperature: -20℃ to 80℃

- Port size: M5x0.8 (standard), optional G1/8/NPT1/8

- Piston material: Aluminum alloy with hard anodizing

- Rod material: Stainless steel (SUS304)

- Seal type: NBR seals (optionally available in FKM)

- Protection rating: IP54 (standard), upgradable to IP67

- Weight: 2.8kg ±3% (excluding accessories)

- Dimensions:

- Total length: 415mm (stroke 300mm + cylinder body)

- Body width: 45mm

- Height with rod: 82mm

- Mounting hole spacing: 25mm x 25mm (SA mount pattern)

Ultra-slim cylinder featuring 18mm reduced height compared to standard models, with built-in stroke adjustment mechanism (manual locking nut). Optimized for space-constrained automation systems requiring precise linear motion control. Includes anti-rotation guide mechanism and wear-resistant bushing for angular misalignment compensation.

- PCB handling robots in electronics manufacturing

- Glass panel pressing mechanisms

- Pharmaceutical blister packaging machines

- Automated door sliding systems

- Precision die-cutting equipment

- Allow minimum 0.5mm thermal expansion gap during mounting

- Use locknuts with 1.2-1.5Nm torque for stroke adjustment mechanism

- Lubricate rod with ISO VG32 hydraulic oil every 3 months

- Magnetic sensor kits (D-A93 series)

- Rod-end shock absorber (MBH20-10)

- Heat-resistant variant (up to 120℃ with FKM seals)

- Corrosion-resistant package (salt spray test 500hrs)

| Property | Property Value |

|---|---|

| sku | ACQJ32X300-30SB |

| Adjustable Stroke | 30mm |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <32 mm> |

| Stroke | 300mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.