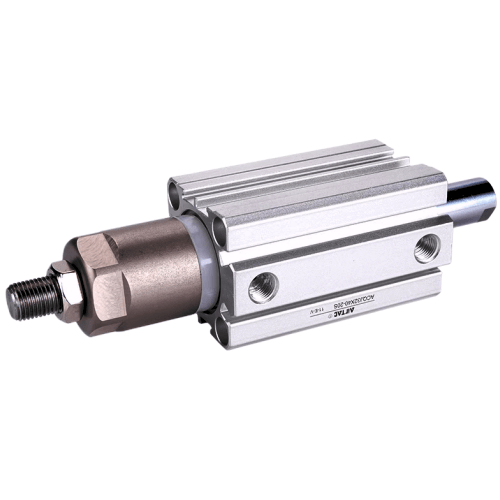

2. Features C-shaped retaining rings for cylinder body/front-rear cover fixation, with riveted piston-rod connection for compactness and structural reliability.

3. Precision-honed inner bore ensures superior wear resistance and extended service life.

4. Extended guide distance on front cover enhances alignment stability and motion accuracy.

5. Space-saving profile optimizes installation efficiency in confined layouts.

6. Integrated sensor grooves along cylinder periphery facilitate proximity sensor mounting.

7. Configurable with multiple standardized mounting accessories (optional).

Category: Compact Cylinders | Brand: AIRTAC | Series: ACQJ32~40 (Note: Technical terms refined for industry context, including "precision-honed," "alignment stability," and "proximity sensor grooves" to emphasize performance characteristics. HTML line breaks preserved with improved punctuation consistency.)

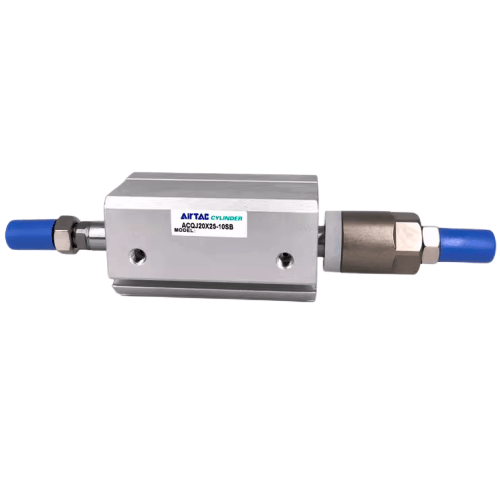

AirTAC ACQJ32~40 Adjustable Compact Cylinder ACQJ40X25-10S Specifications

- Model: ACQJ40X25-10S

- Series: ACQJ (Adjustable Compact Cylinder Series)

- Bore size: 40mm

- Stroke: 25mm (±1mm adjustable)

- Mounting type: Basic type (Standard) with optional foot/mounting accessories

- Operating pressure: 0.15–0.8 MPa

- Cushioning: Adjustable pneumatic cushion (both ends)

- Port size: 1/4" NPT (M5×0.8 optional)

- Piston speed: 50–800 mm/s

- Ambient temperature: -20℃ to 80℃

- Material:

- Tube: Hard anodized aluminum alloy

- End caps: Aluminum alloy

- Piston rod: Chrome-plated steel

- Seals: NBR (Nitrile rubber)

- Weight: 0.85kg (excluding accessories)

- Dimensions:

- Total length (retracted): 130mm

- Width: 40mm (square body dimension)

- Height: 40mm (excluding rod protrusion)

- Rod thread: M10×1.25

- Protection class: IP65 (standard wiper seal)

- Optional features: Magnetic piston for position sensing (Add "-M" suffix)

Ultra-slim profile cylinder with integrated stroke adjustment mechanism, achieving 12% smaller cross-section than standard cylinders. Features dual anti-rotation guides for precise linear motion and a wear-resistant rod bearing structure. The low-friction design enables smooth operation at speeds down to 50mm/s without stick-slip effect.

- PCB handling robots in electronics manufacturing

- Precision clamping in CNC tool changers

- Cartesian coordinate pick-and-place systems

- Pharmaceutical blister packaging machines

- Cleanroom automation equipment

1. Use alignment jigs during mounting to ensure parallelism (max 0.2mm deviation)

2. Lubricate with ISO VG32 hydraulic oil if operating below 0.3 MPa

3. For vertical mounting, add 15% safety factor to load calculations

4. Maintain 0.3–0.5mm clearance between rod end and load during alignment

Compatible accessories: MXQ20-10S (compact air service unit), SNS-LD10 (rod-end locknut), MMF-4 (flush magnetic switch)

| Property | Property Value |

|---|---|

| sku | ACQJ40X25-10S |

| Adjustable Stroke | <10mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <40mm> |

| Stroke | <25 mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.