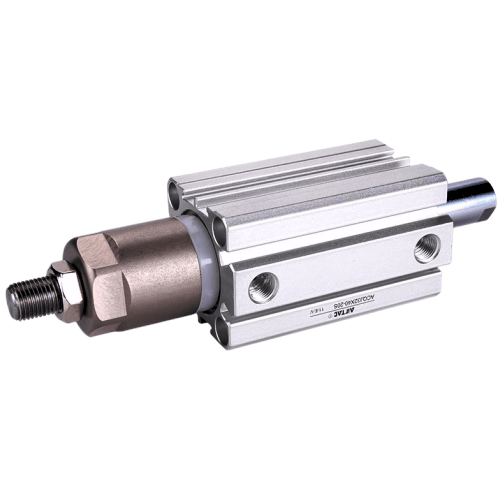

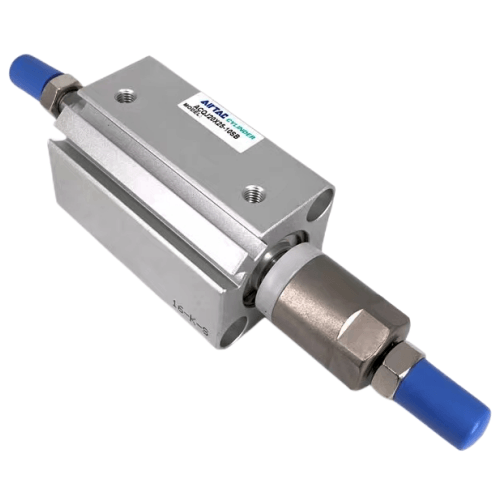

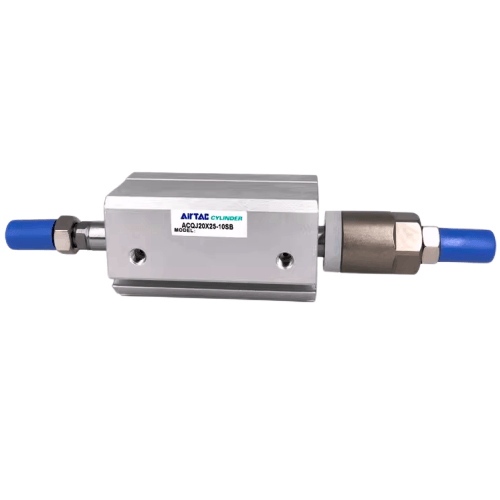

2. C-shaped retaining ring secures cylinder body with front/rear covers; Integrated riveted piston-rod structure ensures compactness and reliability;

3. Cylinder bore features precision honing for enhanced wear resistance and long service life;

4. Extended guide length on front cover delivers superior guiding performance;

5. Space-saving compact design optimizes installation in confined areas;

6. Perimeter sensor grooves enable hassle-free proximity sensor mounting;

7. Multiple standardized mounting accessories available for flexible configurations;

Category: Slim Cylinder | Brand: AIRTAC | Series: ACQJ80~100

AirTAC ACQJ80X125-50SB Adjustable Compact Cylinder Specifications

- Series: ACQJ80~100 Thin-Type Cylinder

- Full Model: ACQJ80X125-50SB

- Bore Size: 80mm

- Stroke: 125mm (adjustable with ±0.5mm precision)

- Operating Pressure: 0.05~0.9 MPa

- Cushioning: Adjustable pneumatic cushion (2-stage damping)

- Mounting Type: 50SB - Rectangular base with through holes

- Port Size: G3/8 (ISO standard)

- Piston Material: Anodized aluminum alloy

- Rod Material: Chrome-plated steel (Cr-Mo)

- Seal Type: NBR + PU hybrid seals

- Temperature Range: -20℃ to 100℃ (dry air required above 70℃)

- Weight: 2.85kg (excluding accessories)

- Dimensions:

- Extended Length: 250mm

- Retracted Length: 125mm

- Body Width: 95mm

- Height with Mount: 108mm

- ISO Standard: 6432 (VDMA 24562)

- Lubrication: Pre-lubricated (Oil-free operation possible)

This ultra-slim cylinder features 23% reduced profile height compared to standard models, with integrated auto-stop mechanism for mid-position locking. The hardened guide bushing ensures precise linear motion, while the double-sealed piston design achieves ≤0.5mm/s creep speed at 0.5MPa. Includes magnetic piston for sensor compatibility.

- High-density automation cells (robotic welding fixtures)

- Semiconductor wafer handling systems

- Vertical CNC tool changers

- Pharmaceutical blister packaging machines

- 3-axis positioning stages with limited Z-height

• Use M6x1.0 mounting screws (25mm min engagement)

• Maintain 0.5mm alignment tolerance during base mounting

• For vertical installations, apply 0.02MPa minimum back pressure

• Cushion adjustment: Turn clockwise to soften end impact (1 full turn ≈ 30% damping force change)

- 50,000km stroke or 2 years (standard air quality)

- Lubrication interval: 3 months (when using oil-free system)

- Rod cover replacement: Every 500,000 cycles

| Property | Property Value |

|---|---|

| sku | ACQJ80X125-50SB |

| Adjustable Stroke | <50mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT3/8 |

| Magnet | S-Magnetic |

| Bore Diameter | 80 mm |

| Stroke | 125mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.