1. Complies with JIS standards;

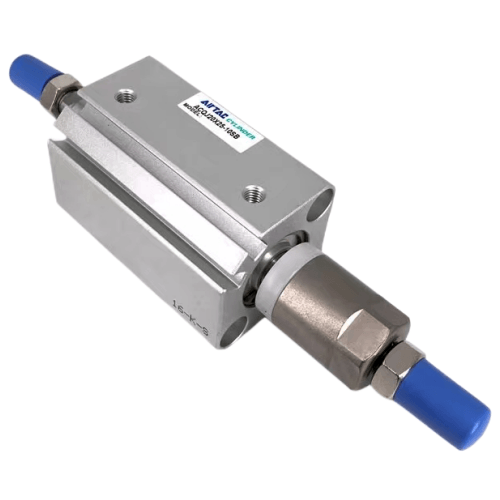

2. C-shaped retaining ring secures cylinder body to front/rear covers, with riveted piston-rod connection for compact and reliable construction;

3. Precision-honed inner bore ensures superior wear resistance and long-term durability;

4. Extended front cover guide length enhances directional stability;

5. Space-saving profile minimizes installation footprint;

6. Perimeter sensor slots enable effortless sensor integration;

7. Multiple mounting accessory configurations available.

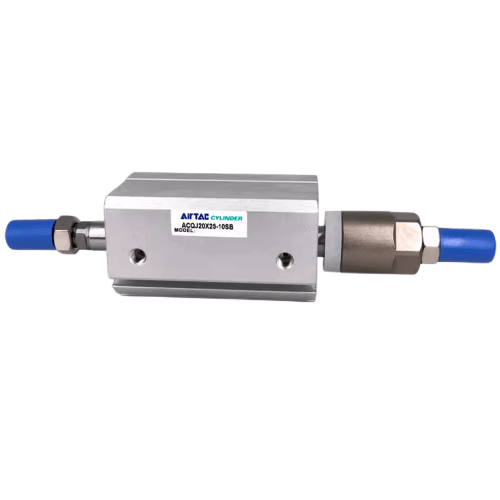

Category: Compact Cylinder | Brand: AIRTAC | Series: ACQJ50~63

AirTAC ACQJ50X70-40S Adjustable Compact Cylinder Specifications

- Model Series: ACQJ50~63 (Cylinder bore range)

- Exact Model: ACQJ50X70-40S

- Type: Double-acting adjustable cushioning cylinder

- Bore size: 50 mm

- Stroke: 40 mm (Standard, customizable 10-300mm)

- Operating pressure: 0.05~0.9 MPa

- Operating temperature: -20℃ to 80℃

- Cushion type: Adjustable buffer + fixed rubber pad

- Mounting style: Basic type (Standard) / CA1 (Swivel base optional)

- Port size: M5x0.8 (Standard), G1/8 optional

- Piston material: Aluminum alloy hard anodized

- Rod material: Stainless steel (SUS304)

- Seal material: NBR/PU hybrid seals

- Weight: 0.68 kg (Body only), 0.92 kg (with accessories)

- Dimensions:

- Body length: 70 mm (Min. retracted length)

- Stroke length: 40 mm

- Total width: 63 mm (With mounting brackets)

- Height: 50 mm (Including piston rod)

- Mounting hole spacing: 36 mm (Standard pattern)

Ultra-slim profile cylinder (14mm thickness reduction vs standard models) with precision-adjustable pneumatic cushioning. Features wear-resistant chromium-plated rod guide and integrated magnet for position sensing. Optional auto-switch compatibility (M9/M12 connectors). Requires 5μm filtered lubricated air (ISO8573-1 class 3).

- PCB handling robots requiring precise stop positioning

- Pharmaceutical blister packaging machines

- Semiconductor wafer transfer mechanisms

- Automated coffee machine brew unit actuation

- Vertical lift systems in cleanroom environments

1. Align mounting surface flatness within 0.1mm

2. Lubricate with ISO VG32 turbine oil during maintenance

3. Allow 2mm thermal expansion gap at stroke ends

4. For vertical mounting, use rod-down orientation to prevent seal wear

| Property | Property Value |

|---|---|

| sku | ACQJ50X70-40S |

| Adjustable Stroke | <40mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT1/4 |

| Magnet | S-Magnetic |

| Bore Diameter | <50mm> |

| Stroke | 70mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.