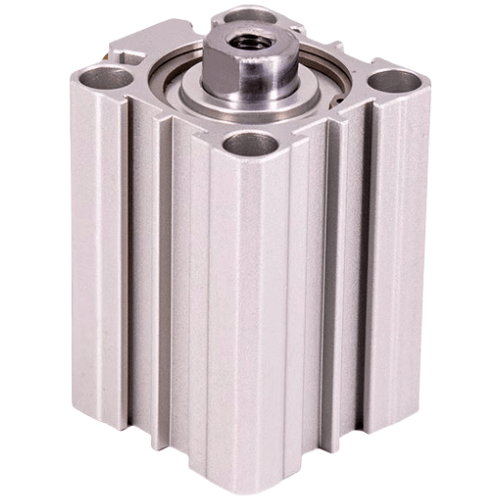

2. Features C-shaped retaining rings for barrel-end cap fixation and riveted piston-rod connection, ensuring structural compactness and reliability;

3. Honed inner diameter barrel surface enhances wear resistance and operational longevity;

4. Extended guide distance on front cap optimizes alignment stability;

5. Space-saving design minimizes installation footprint;

6. Integrated sensor grooves along barrel periphery facilitate easy sensor mounting;

7. Versatile mounting accessories available for multiple configuration options;

Category: Compact Cylinder | Brand: AIRTAC | Series: ASQ Single-Acting Cylinder

AirTAC ASQ63X5 Single-Acting Compact Cylinder Specifications

- Model: ASQ63X5 Series

- Type: Single-acting spring return (piston type)

- Bore size: 63mm

- Stroke range: 5-100mm (standard strokes available in 5mm increments)

- Operating pressure: 0.05-0.9 MPa

- Operating temperature: -20℃ to 80℃

- Port size: M5x0.8 (standard), G1/8 optional

- Cushion type: Fixed rubber buffer

- Seal material: NBR (Nitrile) with wear-resistant ring

- Mounting style: Basic type (multiple mounting options available)

- Weight: 0.56kg (base model with 25mm stroke)

- Dimensions (LxWxH):

- Stroke 25mm: 94mm x 63mm x 63mm

- Stroke 100mm: 169mm x 63mm x 63mm

- Height with mounting feet: +4mm

- Piston speed: 50-700mm/s

- Ambient fluid compatibility: Air (lubricated or non-lubricated)

- ISO standard: Compliant with ISO 6432 (mounting dimensions)

Ultra-slim profile cylinder (only 63mm cross-section) designed for space-constrained automation systems. Features precision-machined aluminum barrel with hard anodized surface treatment (8-12μm) for corrosion resistance. The double-sealed piston design ensures minimal air leakage (≤0.5 NL/min at 0.5MPa). Requires 40μm filtered air and recommends ISO VG32 turbine oil mist lubrication (0.3-1.0g/m³).

- PCB handling robots in electronics manufacturing

- Clamping mechanisms in CNC fixture systems

- Paper feed actuators in printing machinery

- Valve switching in cleanroom equipment

- Packaging machine ejection systems

- Allow ≥2mm clearance around cylinder body for heat dissipation

- Maximum side load: ≤15% of theoretical thrust

- Lubrication interval: 3 months continuous operation (dry air)

- Alignment tolerance: ≤0.2mm angular misalignment

- Recommended maintenance cycle: 5 million strokes or 2 years

| Property | Property Value |

|---|---|

| sku | ASQ63X5 |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | PT1/4 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | Non-magnetic |

| Bore Diameter | 63mm |

| Stroke | <5mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.