2. Enhanced aluminum alloy cylinder body with front/rear threaded connections for superior strength and maintenance convenience;

3. Precision-machined inner bore with hard anodized treatment ensures exceptional wear resistance and durability;

4. Special bidirectional sealing structure on piston for compact dimensions and integrated oil reservoir function;

5. Space-saving compact design optimizes installation space utilization;

6. Built-in magnetic sensing slots on cylinder periphery for simplified sensor mounting and alignment;

7. Multiple mounting accessory configurations available for flexible adaptation;

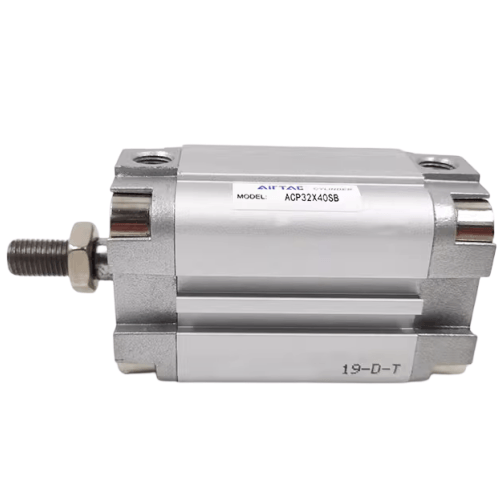

Category: Compact Cylinder | Brand: AirTAC | Series: ATP

AirTAC ATP20X25B Single-Acting Compact Cylinder Specifications

- Model: ATP20X25B

- Type: Single-acting spring return (non-rotating rod)

- Bore size: 20mm

- Stroke: 25mm

- Operating pressure: 0.05–0.9 MPa

- Port size: M5x0.8 (standard), optional NPT1/8

- Cushioning type: Fixed buffer (adjustable upon request)

- Mounting options: Front flange (MF1), foot mounting (MP2), or rear pivot (M9)

- Temperature range: -20℃ to 80℃

- Seal material: NBR (Nitrile rubber), optional FKM

- Piston speed: 50–750 mm/s

- Weight: 220g ±5% (without accessories)

- Dimensions: 80mm(L) × 42mm(W) × 42mm(H) (fully retracted)

- Rod thread: M6x1.0 (external)

- Max theoretical force: 28.3N at 0.5MPa

- Ambient humidity: ≤95% RH (non-condensing)

Ultra-compact pneumatic cylinder optimized for space-constrained automation systems. Features anti-rotation mechanism for precise linear motion control and wear-resistant aluminum alloy construction. Includes built-in magnetic field for sensor compatibility (D-M9 type). Requires ISO 8573-1 class 3 or cleaner compressed air.

- PCB handling robots in electronics assembly

- Precision clamping fixtures for CNC machining

- Medical device actuation systems

- Textile machinery thread tension control

- Automated food packaging pusher mechanisms

- Lubricate with ISO VG32 hydraulic oil before initial use

- Allow 1mm clearance around cylinder body for thermal expansion

- For vertical mounting, use speed controller to prevent piston slam

- Relubrication interval: Every 500km of cumulative stroke

- Seal replacement: 2,000km or 5 years (whichever comes first)

- Magnetic sensor cleaning: Every 6 months in dusty environments

| Property | Property Value |

|---|---|

| sku | ATP20X25B |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | M5×0.8 |

| Piston Rod Thread Type | External Thread |

| Magnet | Non-magnetic |

| Bore Diameter | <20mm> |

| Stroke | <25 mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.