2、C-shaped retaining ring secures cylinder body with front/rear covers, riveted piston-rod structure ensures compactness and reliability;

3、Honed cylinder bore surface enhances wear resistance and long-term durability;

4、Extended guide distance in front cover delivers superior alignment stability;

5、Space-optimized profile minimizes installation footprint;

6、Integrated sensor grooves enable seamless magnetic switch mounting;

7、Multiple standardized mounting accessories available for flexible configurations;

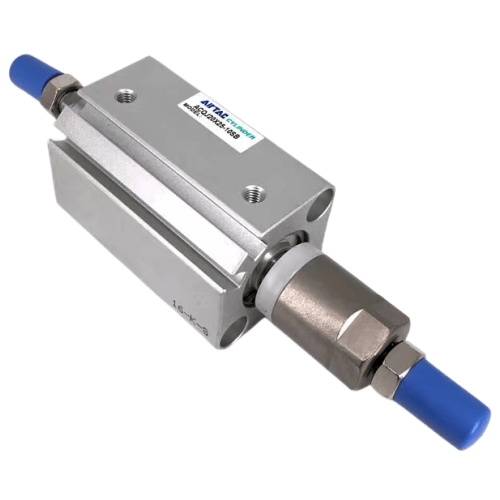

AirTAC B01-ACQJ25X25-20B Special Purpose Cylinder Specifications

- Full Model: B01-ACQJ25X25-20B

- Series: B01-ACQJ (Compact Square Cylinder Series)

- Bore Size: 25mm

- Stroke: 25mm

- Operating Pressure: 0.05-0.9 MPa

- Temperature Range: -20℃ to 80℃

- Cushion Type: Adjustable Air Cushion (Both Ends)

- Mounting Style: 20B (Square Flange with Front Mounting Threads)

- Port Size: M5x0.8 (Standard) / Optional NPT1/8

- Cylinder Tube Material: Aluminum Allody Treatment

- Piston Rod Material: Stainless Steel (SUS304)

- Seal Material: Nitrile Rubber (NBR) + Polyurethane (PU)

- Weight: 0.82kg ±2%

- Dimensions: 200mm(L) × 50mm(W) × 50mm(H) (Fully Extended)

- Rod Thread: M10x1.25 (External Thread)

- Max Speed: 500mm/s

- Protection Rating: IP54 (Standard)

A high-precision compact cylinder featuring dual adjustable pneumatic cushions and anti-rotation mechanism. The square flange design enables stable mounting in confined spaces, with corrosion-resistant construction for humid environments. Includes built-in magnet for position sensing compatibility.

- Precision clamping in CNC tool changers

- Material handling in semiconductor wafer production

- Positioning mechanisms for automated test equipment

- Actuation in food packaging lines (non-contact areas)

- Medical device assembly automation

| Property | Property Value |

|---|---|

| sku | B01-ACQJ25X25-20B |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.