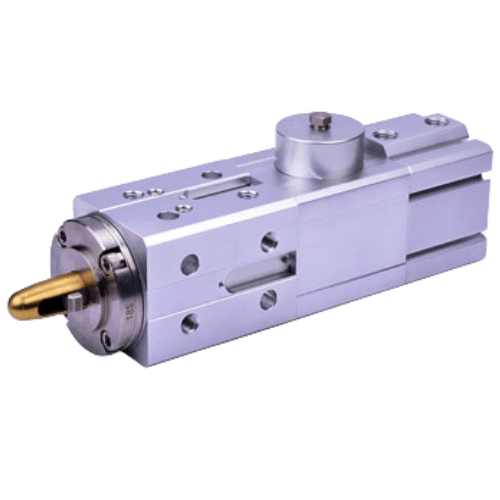

AirTAC BAQK50SAAB2-159X310 Clamp-Type Pin Cylinder Specifications

- Model: BAQK50SAAB2-159X310

- Type: Double-acting clamp-type pin cylinder with magnetic piston

- Bore size: 50 mm

- Stroke: 159 mm

- Operating pressure: 0.1–1.0 MPa

- Operating temperature: -20℃ to 80℃

- Medium: Clean dry air (40μm filtration required)

- Cushioning: Adjustable pneumatic cushion

- Mounting type: Standard foot mounting (ISO 15552 compatible)

- Seal material: NBR + PU hybrid seals

- Port size: G1/4 (BSPP thread)

- Piston rod thread: M16×1.5

- Magnet type: Integrated rare-earth magnet (IP67 rated)

- Weight: 2.85 kg (without accessories)

- Dimensions: 310mm(L) × 72mm(W) × 72mm(H) (excluding rod extension)

- Rod end type: Female thread with anti-rotation flats

- Protection rating: IP65 (dust-tight & water jet resistant)

High-rigidity pin cylinder engineered for precision clamping applications requiring exceptional lateral load resistance. Features dual guide rods and a reinforced mounting base that provides 3x higher moment resistance compared to standard cylinders. The chrome-plated piston rod includes a wear-resistant coating for >3,000km service life under continuous operation.

- Automated welding fixture clamping systems

- CNC machine tool workpiece positioning

- Robotic assembly station press-fitting operations

- Heavy-duty conveyor gate locking mechanisms

- Precision mold alignment in injection molding

| Property | Property Value |

|---|---|

| sku | BAQK50SAAB2-159X310 |

| Clamping Arm Position | Clamping Arm at 90° to Air Inlet |

| Port Size | PT1/4 |

| Body Mounting Dimensions | Mounting Threaded Hole M10×1.5 |

| Magnet | S-Magnetic |

| Bore Diameter | <50mm> |

| Adjustment Shim | With Adjustment Shim 2mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.