Description

1. The electronic temperature sensor features short measurement time, high measurement accuracy, user-friendly readability, and integrated data logging capability.

2. Its architecture consists of four core components: temperature sensing probe, signal processing unit, digital display interface, and regulated power supply module.

3. The temperature sensing probe serves as the sensitive component, typically incorporating one or multiple high-precision rapid-response thermistors, which directly determines measurement reliability through exceptional temperature linearity and millisecond-level response characteristics.

Mounting guidelines:

Maintain 2×sensing distance (16mm) between adjacent sensors.

For flush mounting applications, use non-metallic brackets to prevent

interference. Maximum cable bending radius: 25mm.

Mounting guidelines:

Maintain 2×sensing distance (16mm) between adjacent sensors.

For flush mounting applications, use non-metallic brackets to prevent

interference. Maximum cable bending radius: 25mm.

2. Its architecture consists of four core components: temperature sensing probe, signal processing unit, digital display interface, and regulated power supply module.

3. The temperature sensing probe serves as the sensitive component, typically incorporating one or multiple high-precision rapid-response thermistors, which directly determines measurement reliability through exceptional temperature linearity and millisecond-level response characteristics.

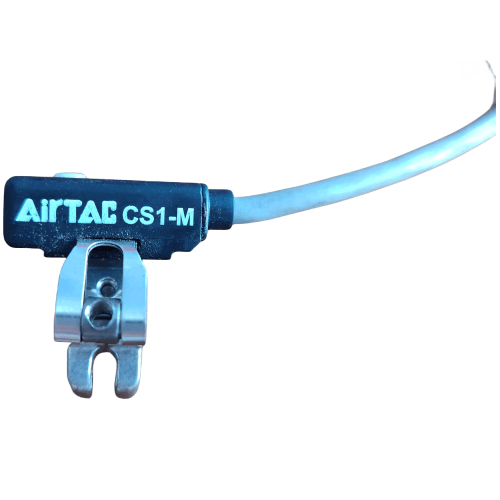

AirTAC DS1MN-C08S25 Electronic Sensor Technical Details

- Model: DS1MNC08S25 (Full code: DS1MN-C08-S25)

- Type: Rectangular DC 3-wire inductive proximity sensor

- Sensing distance: 8mm ±10% (Non-adjustable)

- Output configuration: NPN NO (Normally Open)

- Supply voltage: 10-30V DC (Ripple ≤10%)

- Current consumption: ≤15mA @24V DC

- Output current: ≤200mA (Short-circuit protected)

- Response frequency: 1kHz

- Hysteresis: ≤15% of sensing distance

- Protection rating: IP67 (IEC 60529)

- Housing material: Nickel-plated brass with PBT sensing face

- Operating temperature: -25℃ to +70℃

- Connection type: 2m PVC cable (AWG22) with brown/blue/black wires

- Weight: 128g ±3g

- Dimensions: 40mm(L) × 20mm(W) × 10mm(H)

Industrial-grade inductive sensor featuring reverse polarity protection and surge suppression. The triple-sealed construction with O-ring (Viton material) ensures reliable detection in oil mist environments. Built-in status LED indicates power and detection state.

Installation & Applications:

- Embed in CNC tool changers for tool position verification

- Conveyor belt object counting with metal triggers

- Hydraulic cylinder end-position detection

- Robotic arm joint limit sensing

- Compatible with PLC inputs (Siemens S7, Mitsubishi FX series)

| Property | Property Value |

|---|---|

| sku | DS1MNC08S25 |

Shipping policies

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.

Reviews

Recently Viewed

Explore your recently viewed items, blending quality and style for a refined living experience.