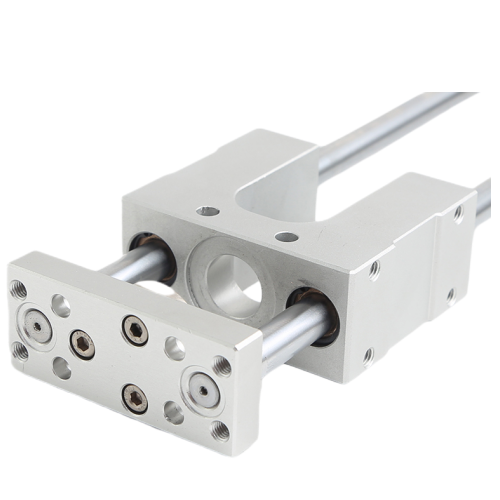

2. Slide Bearing Configuration: Suitable for applications requiring radial load resistance in cylinder operations such as braking, offering enhanced torsional rigidity. Linear Bearing Configuration: Ideal for push-pull cylinder motions, high-precision/high-load scenarios, and applications demanding low-friction movement;

3. Proprietary guide unit body design enables multi-directional mounting configurations for flexible installation.

Category: Guide Units , Brand: AIRTAC , Series: F-TMIC

AirTAC F-TMICM20X250 Individual Guide Bracket Technical Details

- Full model designation: F-TMICM20X250

- Guide type: Precision linear motion shaft support

- Material composition: High-carbon chromium steel core with hard chrome-plated surface

- Surface hardness: HRC 58-62

- Surface roughness: Ra ≤0.2μm

- Shaft diameter: Ø20mm ±0.005mm

- Effective stroke: 250mm (+0/-0.3mm tolerance)

- Max dynamic load capacity: 3,200N (axial), 2,800N (radial)

- Max speed: 2.0m/s continuous operation

- Operating temperature: -15℃ to 100℃ (lubricated)

- Weight: 1.85kg ±2%

- Dimensions: 298mm(L) × 42mm(W) × 38mm(H)

- Mounting hole pattern: 4×M6 threaded holes on 60mm × 40mm PCD

- Surface treatment: Multi-layer corrosion resistance coating (5-8μm)

Precision-ground guide bracket designed for high-accuracy linear motion systems, featuring ultra-low friction coefficients (μ<0.003 when lubricated). The triple-sealed structure integrates dust-resistant labyrinth seals and dual wiper rings, ensuring contamination resistance up to IP54 standards. Requires periodic lubrication intervals of 100km travel or 6 months.

- CNC tool magazine positioning mechanisms

- Automated optical inspection (AOI) equipment stages

- High-speed pick-and-place robot Z-axis guides

- Semiconductor wafer handling systems

- Precision injection molding ejector units

| Property | Property Value |

|---|---|

| sku | F-TMICM20X250 |

| Bore Diameter | <20mm> |

| Bearing Category | Bronze Bushing |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.