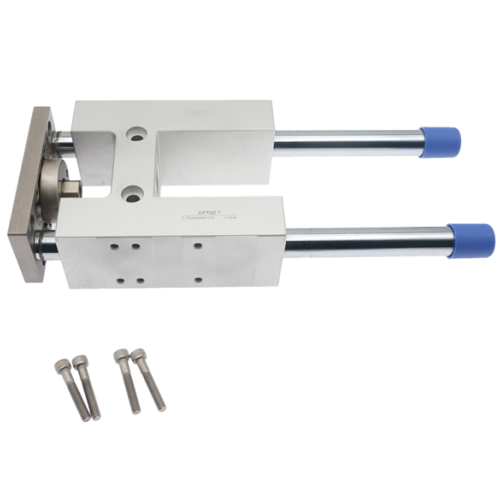

1. Innovative combination of guide mechanism and cylinder in a compact design;

2. Bearing options: Plain bearings (ideal for radial load resistance in braking applications, offering enhanced torsional rigidity); Linear bearings (suited for lifting operations, high-precision/high-load scenarios, and low-friction requirements);

3. Multi-directional mounting configurations enabled by optimized guide unit structural design;

4. Smooth cushioning adjustment for shock-free motion control;

5. Adjustable sensor mounting brackets for flexible positioning to meet application-specific sensing needs.

Category: Guide Units | Brand: AirTAC | Series: F-TSAI (Note: Key technical terms aligned with pneumatic industry standards - "Plain bearings," "Linear bearings," "radial load resistance," "torsional rigidity," and "cushioning adjustment" emphasize functional precision. Structural terms like "multi-directional mounting" and "adjustable sensor brackets" highlight versatility. Brand name retained as "AirTAC" per global nomenclature.)

AirTAC F-TSAIL80X350 Single Axis Guide Unit Technical Specifications

- Model: F-TSAIL80X350

- Type: Linear guide carriage with integrated bearing system

- Material: Aluminum alloy 6063-T5 (anodized surface)

- Rail width compatibility: 80mm series linear guides

- Precision grade: P5 (high precision) ±0.02mm/m

- Max dynamic load capacity: 12,500N (radial), 8,200N (reverse radial)

- Max static load capacity: 24,000N (radial), 15,500N (reverse radial)

- Operating temperature: -10℃ to 80℃

- Sealing: Triple-lip contact seals + stainless steel scrapers

- Lubrication: Pre-lubricated with Molykote PG-641 (5000km service interval)

- Mounting hole pattern: 8×M8 threaded holes (depth 12mm) on 50mm grid

- Anti-corrosion protection: MIL-STD-810G salt spray tested (240hrs)

- Weight: 2.8kg ±5%

- Dimensions: 350mm(L) × 80mm(W) × 48mm(H)

High-rigidity guide carriage featuring dual-row angular contact bearings for multi-directional load support. The hardened stainless steel raceway and optimized ball circuit design ensure smooth motion with ≤0.003mm running parallelism deviation. Includes integrated dust-proof structure with replaceable wipers.

- High-speed CNC tool changer mechanisms

- Semiconductor wafer handling robots

- Precision optical inspection equipment

- Automated warehouse stacker cranes

- Lithium battery production line conveyors

1. Use 0.02mm/m grade straightedge during alignment

2. Apply Loctite 243 on mounting screws (recommended torque 22N·m)

3. Clean guide rail with non-woven cloth soaked in ISOPAR H before assembly

4. Maintain 0.5-1mm clearance between adjacent carriages in multi-unit setups

| Property | Property Value |

|---|---|

| sku | F-TSAIL80X350 |

| Bore Diameter | 80 mm |

| Bearing Category | Linear Bearing |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.