2. Both water and oil bowls utilize space-saving short-type PC construction, ideal for installations with spatial constraints;

3. Equipped with differential pressure manual drainage mechanism for filter condensation discharge.

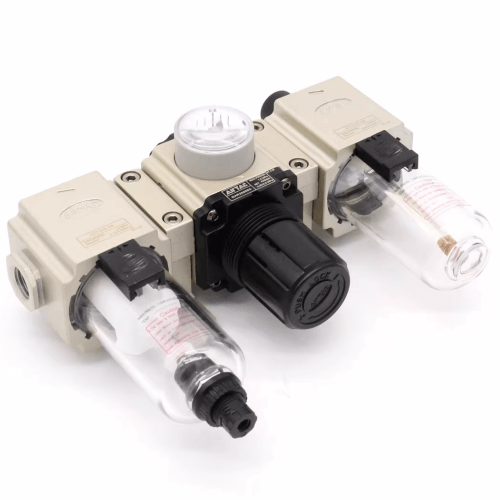

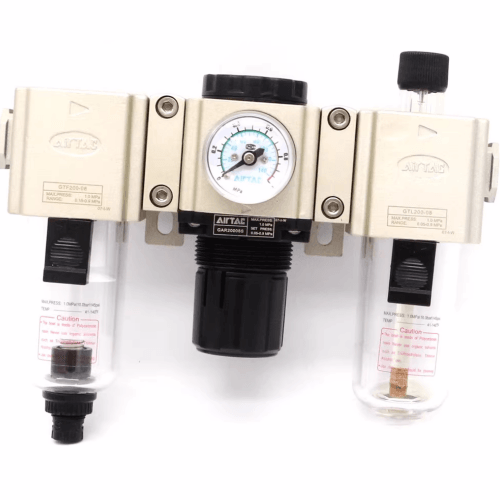

Category: FRL Combination Unit , Brand: AirTAC , Series: GTC

AirTAC GTC Triple Unit GTC20008S Technical Details

- Model: GTC20008S (Triple Unit)

- Component Configuration: Filter + Regulator + Lubricator (FRL)

- Port Size: PT1/2 (BSPP thread)

- Max Operating Pressure: 1.6 MPa

- Filter Element: 40μm sintered bronze (replaceable)

- Pressure Gauge Range: 0-1.0 MPa (standard dial)

- Adjustment Knob: Lockable rotary knob with ±0.02MPa stability

- Body Material: Die-cast aluminum alloy (anodized finish)

- Bowl Material: Polycarbonate (impact-resistant)

- Temperature Range: -5℃ to 60℃ (non-freezing conditions)

- Weight: 1.85 kg (complete assembly)

- Dimensions: 195mm(H) × 140mm(W) × 105mm(D)

- Drain Type: Manual drain button with splash guard

- Lubricator Capacity: 150cc (visible oil level window)

- Flow Rate: 3,500 L/min (ANR)

- Viscosity Range: 70-1500 cSt (ISO VG32 recommended)

Modular FRL unit combining 3-stage air preparation with tool-free bowl removal. Features automatic pressure compensation and anti-clogging filter design. The regulator includes overload protection with built-in relief valve. Optional mounting bracket slots on both sides for rail or panel installation.

- Centralized pneumatic systems in CNC machining centers

- Plastic injection molding machine air lines

- Automated assembly line tooling stations

- Textile machinery lubrication control

- Food packaging equipment (oil-free version available)

| Property | Property Value |

|---|---|

| sku | GTC20008S |

| Port Size | PT1/4 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.