2. Both water and oil bowls utilize space-saving short-type PC construction, ideal for installations with spatial constraints;

3. Equipped with differential pressure manual drainage mechanism for filter condensation discharge.

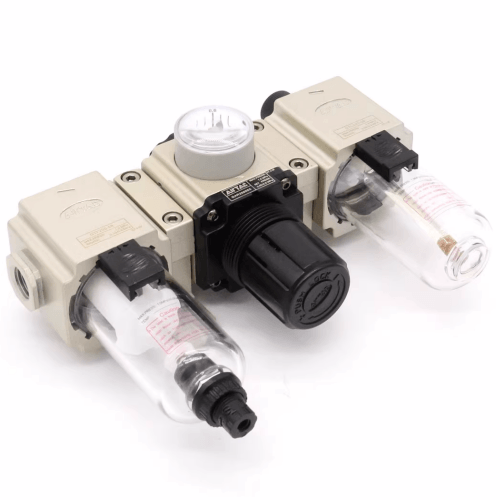

Category: FRL Combination Unit , Brand: AirTAC , Series: GTC

AirTAC GTC Series Triple Unit GTC20008SWK Technical Specifications

- Model: GTC20008SWK

- Type: Integrated FRL Unit (Filter-Regulator-Lubricator)

- Port size: PT1/2 (G1/2 equivalent)

- Operating pressure range: 0.05–0.85 MPa

- Max flow capacity: 3,500 L/min (ANR)

- Filter grade: 5 μm (with auto-drain)

- Regulator accuracy: ±0.02 MPa

- Lubricator oil capacity: 70 cc

- Temperature range: 5℃ to 60℃ (non-freezing)

- Body material: Aluminum alloy (filter bowl: polycarbonate)

- Weight: 3.2 kg (dry)

- Dimensions: 200mm(L) × 150mm(W) × 100mm(H)

- Thread torque rating: 30 N·m max

- Pressure gauge: 40mm dial (0-1.0 MPa scale)

Professional-grade modular FRL unit combining 5μm particulate filtration, precision pressure regulation, and adjustable oil mist lubrication. Features a shatter-resistant polycarbonate bowl with safety guard and quarter-turn bowl lock. The regulator includes a tamper-proof knob with position memory and stainless steel diaphragm for stable output. Includes dual pressure gauge ports (input/output monitoring).

- Centralized pneumatic system conditioning

- High-cycle automation equipment (CNC machines, assembly robots)

- Food packaging lines (USDA/FDA compliant materials)

- Industrial tool air supply stations

- Plastic injection molding machines

| Property | Property Value |

|---|---|

| sku | GTC20008SWK |

| Port Size | PT1/4 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.