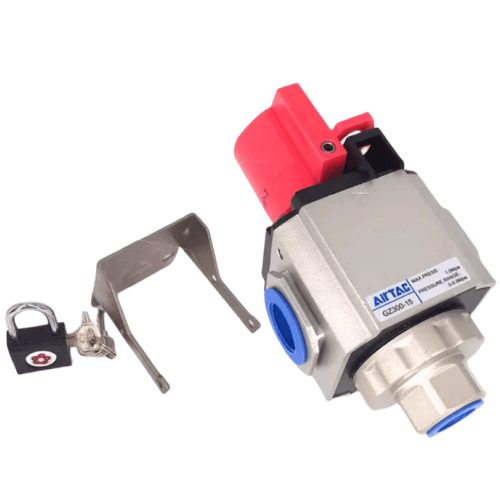

1. Modular design with bracket compatibility for integration with G/GA series FRL units;

2. Configurable as manual three-way valve operation;

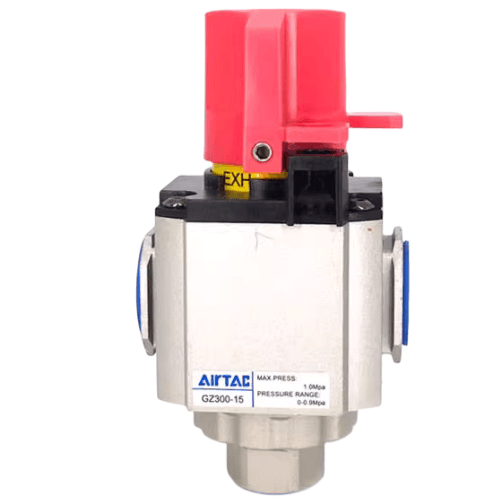

3. Visual confirmation of operational status through EXH./SUP. indicator markings;

4. OSHA-compliant safety mechanism: Features lockable actuator and integrated exhaust valve that simultaneously vents residual pressure while shutting off air supply during maintenance. This prevents accidental pressurization of downstream circuits by third-party interference, ensuring compliance with OSHA 29 CFR 1910.147 requirements for control of hazardous energy (lockout/tagout).

Category: Shut-off Valve | Brand: AIRTAC | Series: GZ

AirTAC GZ Series Shut-Off Valve GZ20006J Technical Details

- Model: GZ20006J

- Type: Manual reset 2-port shut-off valve

- Thread standard: G1/8 (BSPP)

- Pressure range: 0.05-1.0 MPa

- Max operating pressure: 1.5 MPa

- Flow coefficient (Cv): 0.15

- Body material: Brass (CuZn39Pb3) with nickel plating

- Seal material: HNBR (Hydrogenated Nitrile) + FKM (Fluorocarbon)

- Temperature range: -20℃ to 150℃ (with FKM seals)

- Weight: 320g ±5%

- Dimensions: 58mm(L) × 42mm(W) × 28mm(H)

- Port spacing: 18mm center-to-center

- Actuation torque: ≤1.5 N·m

- Leakage rate: ≤3 bubbles/min (ISO 5208 Class B)

Positive shut-off valve with quarter-turn manual operation, featuring dual-seal structure for fail-safe fluid isolation. The chrome-plated brass construction ensures corrosion resistance in humid environments, while the fluorocarbon seals enable compatibility with aggressive media including oils and mild chemicals.

- Emergency isolation in pneumatic conveyor systems

- Maintenance safety cutoff for hydraulic test benches

- Process interruption in chemical dosing lines

- Vacuum system protection in semiconductor equipment

- Coolant flow control in CNC machining centers

| Property | Property Value |

|---|---|

| sku | GZ20006J |

| Number of Positions | 3-Port 2-Position |

| Exhaust Port Size | PT1/4 |

| Port | PT1/8 |

| Bracket Code | Without bracket |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.