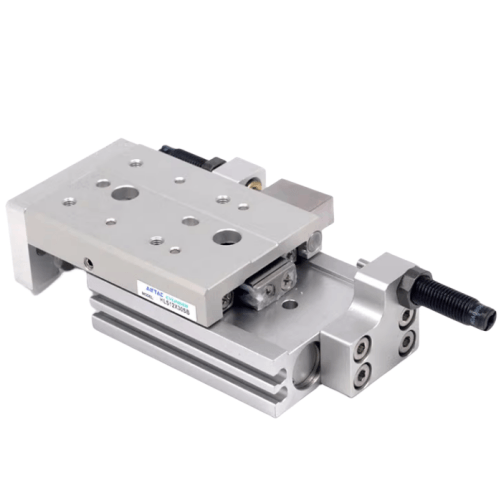

2. Pre-machined positioning pin holes integrated into guide rail;

3. Floating joint design prevents piston rod from bearing additional load moments;

4. Dual piston rod configuration delivers double output force;

5. Built-in positioning pin holes on main body;

6. Mounting screw holes on both base surface and end faces for versatile installation.

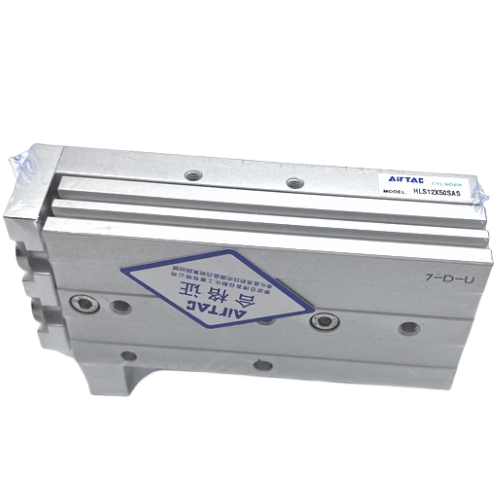

Category: Precision Slide Cylinder , Brand: AIRTAC , Series: HLS

AirTAC HLS Precision Slide Cylinder HLS12X75S Technical Details

- Model: HLS12X75S

- Series: HLS (High-Precision Linear Slide Series)

- Bore size: 12mm (Cylinder diameter)

- Stroke: 75mm (±0.5mm tolerance)

- Structure: Single-axis compact design with integrated linear guide

- Material: Aluminum alloy body (A6063-T5) with hard anodized surface

- Rod material: Stainless steel (SUS304) with chrome plating (2-3μm)

- Seals: NBR + PU combination for low friction and high wear resistance

- Operating pressure: 0.1-0.8 MPa (14.5-116 psi)

- Cushioning: Adjustable hydraulic shock absorber (both ends)

- Repeat positioning accuracy: ±0.01mm

- Max thrust: 19.6N at 0.5MPa (Push/Pull force varies by pressure)

- Max lateral load: 5.4N·m

- Max speed: 500mm/s (With cushioning engaged)

- Weight: 0.85kg (Excluding mounting accessories)

- Dimensions:

- Total length: 165mm (Stroke 75mm + Body 90mm)

- Body width: 45mm (Including guide rails)

- Height: 45mm (Mounting surface to top of rail)

- Mounting options: Front flange (MF1), Side mounting (MS1), or base mounting

- Temperature range: -20℃ to 80℃ (Dry air required below 0℃)

- Lubrication: Pre-lubricated (Relubrication interval: 1,000km travel)

- Accessory compatibility: Magnetic sensors (e.g., D-A93 series) can be installed

- Protection class: IP40 (Dust protected)

The HLS12X75S combines pneumatic actuation with precision linear guidance in a space-saving package. Its dual-sealed guide structure minimizes play (<0.05mm) while maintaining smooth motion, ideal for applications requiring both force delivery and positional accuracy. Features integrated T-slot mounting channels for accessory attachment.

- PCB component insertion machines

- Lens polishing equipment positioning stages

- Semiconductor wafer handling arms

- Automated optical inspection (AOI) systems

- 3D printer Z-axis calibration mechanisms

- 10,000km travel distance under standard load (25℃, 0.5MPa)

- Replace guide blocks after 5 million cycles or when play exceeds 0.1mm

| Property | Property Value |

|---|---|

| sku | HLS12X75S |

| External Stop Block Type | No External Stops |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | M5×0.8 |

| Magnet | S-Magnetic |

| Bore Diameter | 12mm |

| Stroke | 75mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.