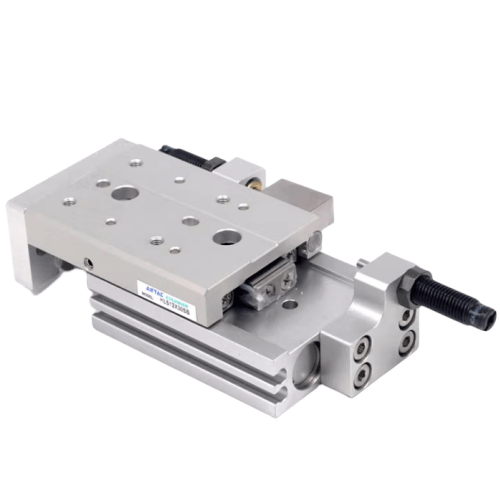

2. Pre-machined positioning pin holes integrated into guide rail;

3. Floating joint design prevents piston rod from bearing additional load moments;

4. Dual piston rod configuration delivers double output force;

5. Built-in positioning pin holes on main body;

6. Mounting screw holes on both base surface and end faces for versatile installation.

Category: Precision Slide Cylinder , Brand: AIRTAC , Series: HLS

AirTAC HLS6X10SAS Precision Slide Cylinder Specifications

- Model: HLS6X10SAS

- Type: Guided rod slide cylinder (dual-axis)

- Bore size: 6mm

- Stroke: 10mm (±0.5mm adjustability)

- Operating pressure: 0.1-0.7 MPa

- Temperature range: -20℃ to 80℃

- Cylinder material: Hard anodized aluminum alloy

- Rod material: Stainless steel (SUS304)

- Buffer type: Adjustable air cushion (both ends)

- Port size: M5x0.8

- Repeat positioning accuracy: ±0.01mm

- Max speed: 500mm/s

- Lubrication: Pre-lubricated (Grease)

- Mounting style: Side mounting holes (4xM3 threaded)

- Seal material: NBR

- Weight: 0.35kg (excluding accessories)

- Dimensions: 120mm(L) × 20mm(W) × 20mm(H)

High-precision linear motion solution with dual-guide rod stabilization, featuring micron-level repeatability. Integrated T-slot design allows direct mounting of sensors or tooling plates. Anti-rotation mechanism ensures smooth linear travel even under eccentric loads. Requires filtered (5μm), lubricated air supply for optimal performance.

- Precision positioning in semiconductor wafer handling

- Lens alignment systems in optical equipment

- Micro-dispensing machines for electronics assembly

- Laboratory automation requiring vibration-free movement

- Medical device component insertion mechanisms

| Property | Property Value |

|---|---|

| sku | HLS6X10SAS |

| External Stop Block Type | Front End Stroke Adjustment Screw |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | M5×0.8 |

| Magnet | S-Magnetic |

| Bore Diameter | <6mm> |

| Stroke | <10mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.