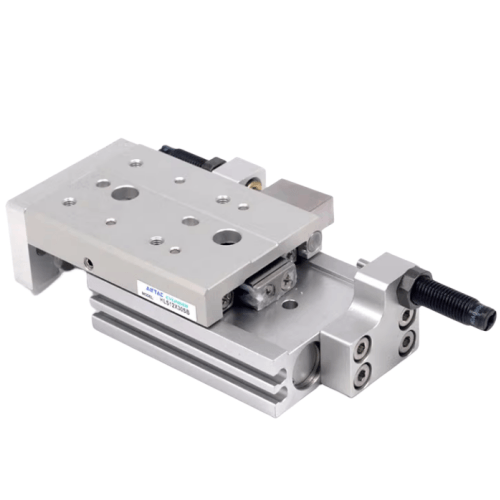

2、Pre-equipped positioning pin holes on guide rail for accurate mounting

3、Floating joint design prevents piston rod from bearing additional torsional loads

4、Dual piston rod configuration achieves double output force

5、Integrated positioning pin holes on main body for secure installation

6、Mounting screw holes provided on base surface and end faces

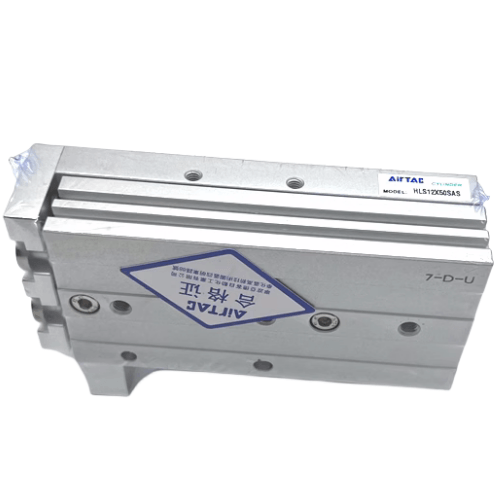

Category: Precision Slide Cylinder , Brand: AirTAC , Series: HLSL

AirTAC HLSL25X30SAS Precision Slide Table Cylinder Specifications

- Model: HLSL25X30SAS

- Bore size: 25mm

- Stroke: 30mm (±0.5mm tolerance)

- Mounting type: Square flange SAS series

- Material: Hard-anodized aluminum body, hardened stainless steel guide rod

- Operating pressure: 0.1-0.9 MPa (14.5-130.5 PSI)

- Temperature range: -20℃ to 80℃ (non-freezing)

- Cushioning: Adjustable pneumatic cushion at both ends

- Repeat positioning accuracy: ≤±0.01mm

- Lubrication: Pre-lubricated (Oil-free operation compatible)

- Seal material: Heat-resistant NBR/PU combination

- Max sliding speed: 500mm/s (with cushioning)

- Guide mechanism: Dual linear ball bearings

- Load capacity: 60N radial / 150N axial (dynamic)

- Port size: M5x0.8 (Dual ports for forward/reverse operation)

- Weight: 1.8kg (including all mounting hardware)

- Dimensions: 200mm(L) × 42mm(W) × 42mm(H) (Stroke extended position)

- Protection rating: IP54 (standard wiper seal)

High-precision linear motion cylinder with integrated guide rails, designed for micron-level positioning stability. Features low-friction dual ball bearing guidance and thermal-stable construction that minimizes positional drift. The hardened steel guide rod undergoes special surface treatment (TiN coating optional) for wear resistance. Compatible with vacuum environments when paired with optional seals.

- Semiconductor wafer handling robots

- Precision optical alignment systems

- Medical device assembly stations

- 3C industry automated testing equipment

- Laser marking machine XY stages

- High-speed pick-and-place mechanisms

1. Maintain 0.02mm/m alignment tolerance during mounting

2. Use torque wrench for mounting bolts (spec: 3.5N·m ±10%)

3. For vertical installations, add mechanical brake for safety

4. Requires 5μm filtered dry air with ISO 8573-1:2010 Class 3.4.2

Achieve 0.005mm positioning repeatability when paired with AirTAC MPM2 series proportional valve and SMC8 magnetic sensor. Maximum cycle rate: 1200 cycles/min (with optimal load balancing).

| Property | Property Value |

|---|---|

| sku | HLSL25X30SAS |

| External Stop Block Type | Front End Stroke Adjustment Screw |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <25 mm> |

| Stroke | 30mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.