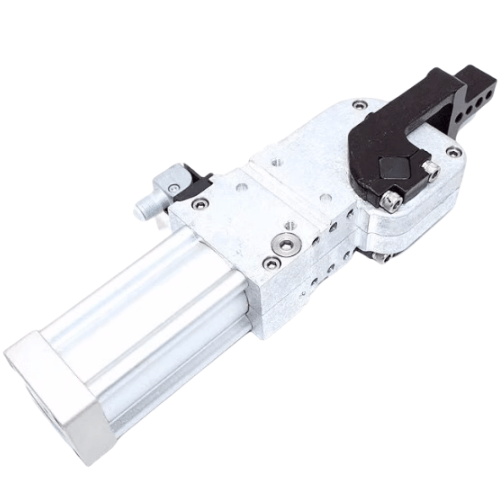

1. Patented crank-slider mechanism (constructed with high-strength, wear-resistant materials): a) Ensures structural stability and generates exceptional clamping force with minimal air pressure through high mechanical efficiency. b) Integrated self-locking mechanism maintains clamping force even during air supply interruption.

2. DIN-compliant four-side mounting configuration for flexible installation options.

3. Monolithic design integrating clamping mechanism with pneumatic cylinder for enhanced structural integrity.

4. Specially engineered sensor bracket with anti-spatter design and ±15° adjustable angles, featuring anti-interference shielding for stable signal transmission.

5. Space-efficient oval-shaped cylinder housing optimizes equipment layout in confined spaces.

6. Modular clamp arms (AM1/AM2/AM3/AM4) with R/C/L variants (radial/vertical/lateral orientations) adapt to diverse operational demands.

7. Tool-free opening angle adjustment via replacement of adjustment screws (15°-180° range).

Category: Welding Clamping Cylinders | Brand: AIRTAC | Series: JCK

AirTAC JCK40X105AM3R Heavy-Duty Welding Clamp Cylinder Specifications

- Model: JCK40X105AM3R

- Type: Double-acting welded rod clamping cylinder

- Bore size: 40mm

- Stroke: 105mm

- Operating pressure: 0.2–1.0 MPa

- Operating temperature: -10℃ to 80℃

- Cushioning: Adjustable rubber buffer + fixed cushion pad

- Mounting style: MF3R (Front rectangular flange with rod rotation prevention)

- Port size: G1/8 (NPT1/8 optional)

- Rod end: M16×1.5 external thread

- Material: Aluminum alloy barrel (hard anodized), CR12MoV piston rod (hard chrome plated)

- Seal type: NBR + special wear-resistant ring

- Protection rating: IP54 (standard), IP67 (optional wiper upgrade)

- Weight: 2.85 kg ±2%

- Dimensions:

- Extended length: 310mm

- Retracted length: 205mm

- Flange width: 90mm

- Overall height: 62mm

- Accessories: Built-in magnetic switch groove (sensor compatible)

Industrial-grade clamping cylinder engineered for high stability in welding fixtures and heavy-load positioning. Features anti-rotation mechanism and reinforced weld structure capable of withstanding 15,000N static load. The chrome-plated piston rod resists spatter adhesion in welding environments. Requires 5μm filtered air with lubricator (ISO VG32 recommended).

- Robotic welding jigs in automotive manufacturing

- Sheet metal press brake tooling fixation

- Foundry mold clamping systems

- Heavy component assembly positioning

- Forge press ejection mechanisms

| Property | Property Value |

|---|---|

| sku | JCK40X105AM3R |

| Clamping Arm Position Code | Clamping Arm Horizontal |

| Clamping Arm Model Code | Offset 45mm |

| Opening Angle | 105mm |

| Port Size | PT1/8 |

| Bore Diameter | <40mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.