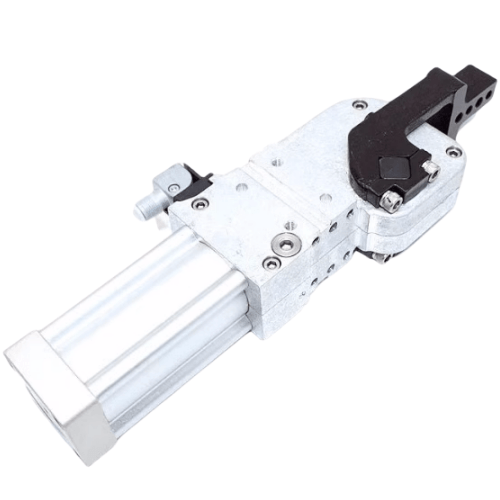

1. Patented crank-slider mechanism (constructed with high-strength, wear-resistant materials): a) Ensures structural stability and generates exceptional clamping force with minimal air pressure through high mechanical efficiency. b) Integrated self-locking mechanism maintains clamping force even during air supply interruption.

2. DIN-compliant four-side mounting configuration for flexible installation options.

3. Monolithic design integrating clamping mechanism with pneumatic cylinder for enhanced structural integrity.

4. Specially engineered sensor bracket with anti-spatter design and ±15° adjustable angles, featuring anti-interference shielding for stable signal transmission.

5. Space-efficient oval-shaped cylinder housing optimizes equipment layout in confined spaces.

6. Modular clamp arms (AM1/AM2/AM3/AM4) with R/C/L variants (radial/vertical/lateral orientations) adapt to diverse operational demands.

7. Tool-free opening angle adjustment via replacement of adjustment screws (15°-180° range).

Category: Welding Clamping Cylinders | Brand: AIRTAC | Series: JCK

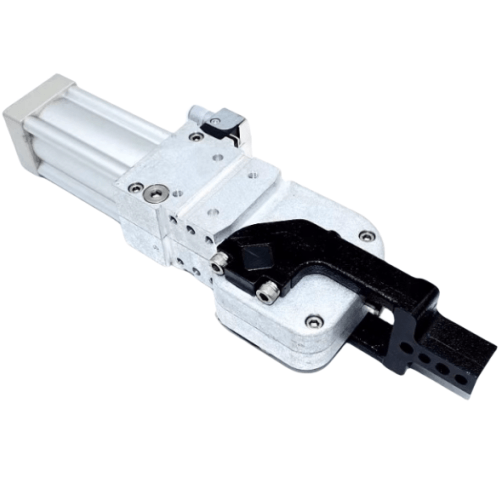

AirTAC JCK40X90AM3C Heavy-Duty Welding Clamp Cylinder Specifications

- Model: JCK40X90AM3C

- Type: Double-acting welded clamp cylinder

- Bore size: 40mm

- Stroke: 90mm (±0.5mm tolerance)

- Operating pressure: 0.1–1.0 MPa

- Temperature range: -10℃ to 150℃ (heat-resistant variant)

- Cushioning: Adjustable hydraulic buffer (front/rear)

- Mounting type: M3X0.5 threaded front flange

- Port size: Rc1/8 (NPT1/8 optional)

- Seal material: Heat-resistant NBR + PTFE composite

- Piston rod material: Hard chrome-plated SCM435 steel

- Tube material: Aluminum alloy with oxidation-resistant coating

- Weight: 2.85kg (dry), 3.1kg (with standard lubrication)

- Dimensions: 190mm(L) × 64mm(W) × 64mm(H)

- Rod end thread: M12×1.25 (male)

- Protection rating: IP67 (wipers included)

- Lubrication: Pre-lubed (VG68 oil), maintenance interval: 2,000km operation

Industrial-grade clamp cylinder specifically engineered for high-temperature welding environments, featuring enhanced thermal shielding and anti-spatter design. The M3X0.5 mounting flange enables secure fixation in vibration-intensive applications. Special chrome-plated rod surface resists weld spatter adhesion (requires optional protective sleeve for arc welding).

- Robotic welding fixture systems (automotive body shops)

- High-frequency spot welding machine clamping

- Forging press part positioning

- Heat treatment furnace door sealing mechanisms

- Battery pack assembly line welding stations

| Property | Property Value |

|---|---|

| sku | JCK40X90AM3C |

| Clamping Arm Position Code | Clamping Arm Horizontal |

| Clamping Arm Model Code | Offset 45mm |

| Opening Angle | 90mm |

| Port Size | PT1/8 |

| Bore Diameter | <40mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.