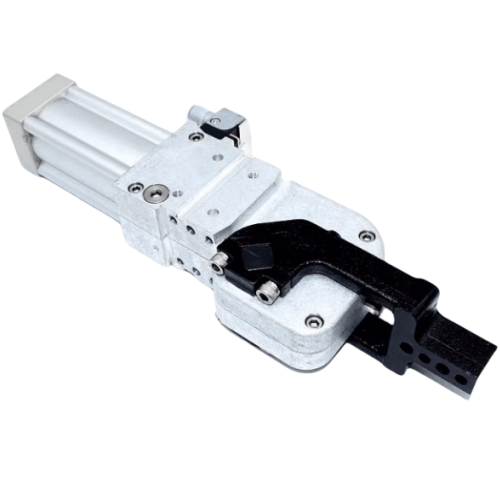

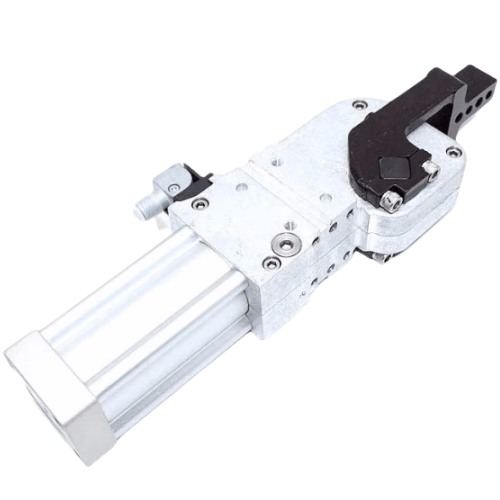

1. Patented crank-slider mechanism (constructed with high-strength, wear-resistant materials): a) Ensures structural stability and generates exceptional clamping force with minimal air pressure through high mechanical efficiency. b) Integrated self-locking mechanism maintains clamping force even during air supply interruption.

2. DIN-compliant four-side mounting configuration for flexible installation options.

3. Monolithic design integrating clamping mechanism with pneumatic cylinder for enhanced structural integrity.

4. Specially engineered sensor bracket with anti-spatter design and ±15° adjustable angles, featuring anti-interference shielding for stable signal transmission.

5. Space-efficient oval-shaped cylinder housing optimizes equipment layout in confined spaces.

6. Modular clamp arms (AM1/AM2/AM3/AM4) with R/C/L variants (radial/vertical/lateral orientations) adapt to diverse operational demands.

7. Tool-free opening angle adjustment via replacement of adjustment screws (15°-180° range).

Category: Welding Clamping Cylinders | Brand: AIRTAC | Series: JCK

AirTAC JCK50X105AM2RK Heavy-Duty Welding Clamping Cylinder Specifications

- Model: JCK50X105AM2RK

- Type: Double-acting welded rod clamping cylinder

- Bore size: 50mm (ISO standard)

- Stroke: 105mm (±1mm tolerance)

- Operating pressure: 0.1–0.8 MPa

- Mounting style: Front flange (ISO 15552 compliant)

- Cushioning: Adjustable pneumatic cushion (both ends)

- Magnetic switch: Built-in M9 (2-wire) with LED indicator

- Port size: G1/4 (BSPP thread)

- Operating temperature: -10℃ to 150℃ (high-temp seals)

- Piston rod material: Hard chrome-plated stainless steel (SUS304)

- Cylinder tube: Anodized aluminum alloy

- Weight: 3.2kg (without accessories)

- Dimensions: 200mm(L) × 58mm(W) × 58mm(H) (at full retraction)

- Rod thread: M20×1.5 external thread (ISO 12240-1)

- Weld tolerance: Withstands 180°C continuous heat exposure

- IP rating: IP67 (dust/water resistant)

Specialized clamping cylinder with reinforced weld structure for high-moment applications. Features tungsten-carbide coated guide rings and high-temperature NBR seals (FDA compliant). Includes dual shock absorbers for >500,000 cycle durability. Requires 5μm filtered air with ISO VG32 lubricant.

- Robotic welding fixture positioning systems

- High-temperature automotive part assembly

- Forging press mold clamping mechanisms

- Shipbuilding jig retention systems

- Heavy-duty CNC machining center workholding

| Property | Property Value |

|---|---|

| sku | JCK50X105AM2RK |

| Clamping Arm Position Code | Clamping Arm Horizontal |

| Clamping Arm Model Code | Offset 15mm |

| Opening Angle | 105mm |

| Port Size | PT1/4 |

| Bore Diameter | <50mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.