2. High Rigidity Four-Directional Equal Load Design: Incorporates 4-row ball circuits with 45° contact angle configuration, achieving optimal two-point contact for bidirectional radial/lateral load capacity. Optional preload application enhances system rigidity when required.

3. Interchangeability: Stringent manufacturing precision ensures dimensional consistency within stable tolerances. Integrated retainer design prevents ball dislodgement, enabling between and matching guideways while preserving operational smoothness, preload integrity, and motion accuracy.

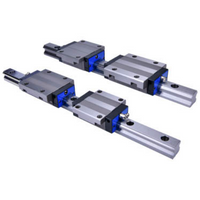

Category: Linear Guides | Brand: AIRTAC | Series: LSH

AirTAC LSH15HN1X570S15AN-M4 Linear Guide Rail Specifications

- Model: LSH15HN1X570S15AN-M4

- Series: LSH Heavy Load Precision Series

- Rail width: 15mm

- Carriage quantity: Single block (1X)

- Effective travel length: 570mm

- Mounting hole pattern: M4 threaded (4.2mm drill size)

- Dynamic load capacity (radial): 4.2kN

- Static load capacity (radial): 8.5kN

- Dynamic moment ratings:

- Mx (pitch): 185 N·m

- My (yaw): 240 N·m

- Mz (roll): 210 N·m

- Precision grade: Normal class (±15μm/300mm)

- Material: High carbon chromium bearing steel (SUJ2 equivalent)

- Surface treatment: Black oxide coating (3-5μm)

- Sealing: Triple labyrinth seal with stainless steel scrapers

- Operating temperature: -20℃ to 100℃

- Weight: 0.52kg (rail) + 0.38kg (carriage) = 0.9kg total

- Dimensions: 570mm(L) × 15mm(Rail width) × 20mm(Height)

High-rigidity linear guide optimized for precision positioning in contaminated environments. Features hardened raceways (HRC 58-62) and preloaded ball circuits for minimal deflection under combined loads. The corrosion-resistant coating and triple sealing system (including oil-retaining felt) ensure reliable operation in dusty or humid conditions.

- CNC tool changer mechanisms

- Semiconductor wafer handling robots

- Medical imaging equipment slides

- Automated optical inspection (AOI) systems

- Precision grinding machine cross-feeds

1. Clean mounting surfaces (flatness ≤0.02mm/m)

2. Tighten bolts in diagonal sequence (1.2-1.5N·m torque)

3. Apply lithium soap-based grease (NLGI #2) during assembly

4. Avoid cantilever loads exceeding 1:3 ratio to rail length

| Property | Property Value |

|---|---|

| sku | LSH15HN1X570S15AN-M4 |

| Slider Width | <15mm> |

| Slide Block Type | Square Body |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.