2. High Rigidity Four-Directional Equal Load Design: Incorporates 4-row ball circuits with 45° contact angle configuration, achieving optimal two-point contact for bidirectional radial/lateral load capacity. Optional preload application enhances system rigidity when required.

3. Interchangeability: Stringent manufacturing precision ensures dimensional consistency within stable tolerances. Integrated retainer design prevents ball dislodgement, enabling between and matching guideways while preserving operational smoothness, preload integrity, and motion accuracy.

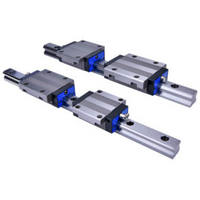

Category: Linear Guides | Brand: AIRTAC | Series: LSH

AirTAC LSH25HN2X2100T2100AH-M6 Linear Guide Rail Specifications

- Model: LSH25HN2X2100T2100AH-M6

- Series: LSH heavy-load precision series

- Rail width: 25mm

- Rail height: 20mm

- Carriage length: 100mm (HN-type block)

- Total length: 2100mm (rail + machining allowance)

- Effective track length: 2070mm

- Mounting hole spacing: 60mm (standard pattern)

- Mounting hole size: M6×1.0 threaded

- Dynamic load capacity: 12.5kN (C)

- Static load capacity: 23.5kN (C0)

- Precision grade: Normal (C-class)

- Material: Carbon steel with chrome plating (rail), Aluminum alloy (carriage)

- Seal type: Triple-lip rubber seals with wipers

- Temperature range: -20℃ to 80℃

- Protection rating: IP54 (standard seals)

- Weight: 10.8kg (rail only), 1.3kg/carriage (total system weight ~13.4kg)

- Dimensions: 2100mm(L) × 25mm(W) × 45mm(H) (rail with mounted carriages)

High-rigidity linear motion system with hardened steel rails and optimized ball circuit design. Features pre-loaded ball bearings for minimal backlash, corrosion-resistant plating, and dust-resistant seals. The HN-series carriage includes 6-row ball contact points for enhanced moment load capacity. Requires periodic lubrication (recommended interval: 100km travel or 6 months).

- CNC machine tool X/Y-axis positioning

- Automated material handling systems

- Precision optical inspection equipment

- Industrial robot linear axis extensions

- High-speed packaging machinery

- 3D printer gantry systems

1. Use alignment gauge (PN: AG-25LSH) during mounting

2. Tighten M6 bolts in cross pattern at 5.5N·m torque

3. Maintain 0.02mm/m straightness tolerance during rail assembly

4. Apply lithium complex grease to mounting surfaces for thermal compensation

| Property | Property Value |

|---|---|

| sku | LSH25HN2X2100T2100AH-M6 |

| Slider Width | 23mm |

| Slide Block Type | Square Body |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.