1. Manufactured in compliance with AirTAC corporate standards;

2. Features custom bidirectional sealing profile with compact dimensions and integrated oil reservoir design for enhanced piston lubrication;

3. Equipped with fixed cushioning pads on both end caps to mitigate directional reversal impact;

4. Multiple rear cover configurations ensure versatile mounting flexibility;

5. Stainless steel barrel and end caps assembled through combined riveting and encapsulation process for robust connection;

6. Precision-engineered from high-grade stainless steel tubing offering exceptional corrosion resistance and structural integrity;

7. Comprehensive selection of cylinder specifications and mounting accessories available for customized applications;

8. Full-range magnetic version standard across series.

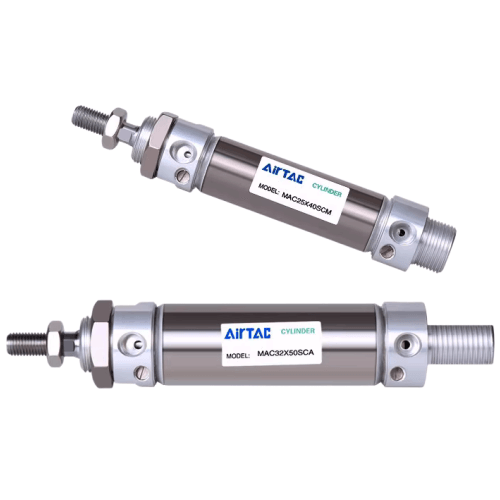

Category: Stainless Steel Miniature Cylinders | Brand: AirTAC | Series: MAC

AirTAC MAC20X160SCMLB Stainless Mini Cylinder Specifications

- Model: MAC20X160SCMLB

- Bore size: 20mm

- Stroke: 160mm (±0.5mm tolerance)

- Operating pressure: 0.05–1.0 MPa

- Temperature range: -10℃ to 150℃

- Cushion type: Adjustable rubber buffer (both ends)

- Port thread: M5×0.8 (standard), G1/8 optional

- Rod end: Female thread M6×1.0

- Mounting type: LB series - front flange with tapped holes

- Material: SUS304 stainless steel (body), CR12MoV piston rod

- Seal material: Fluororubber (FKM)

- Protection rating: IP67

- Weight: 850g ±2%

- Dimensions:

- Total length (L): 235mm (at mid-stroke)

- Body width (W): 35mm

- Height with mount (H): 52mm

- Mounting center distance: 25mm × 25mm

- Rod thread protrusion: 12mm

High-precision stainless steel mini cylinder designed for harsh environments requiring corrosion resistance and compact force. Features laser-etched position markers and dual anti-rotation guides for precise linear motion. Compatible with magnetic sensors (sensor groove: 6.5mm × 1.5mm).

- Cleanroom automation in semiconductor manufacturing

- Food processing machinery (NSF-compliant design)

- Medical device actuation systems

- High-temperature paint spraying equipment

- Marine environment automation controls

1. Use 20-30N·m torque for mounting screws (M4×12 specified)

2. Lubricate with ISO VG32 hydraulic oil before initial use

3. Maintain ≤0.5mm alignment tolerance during rod-end loading

4. For vertical mounting, add 15% extra force margin for gravity compensation

| Property | Property Value |

|---|---|

| sku | MAC20X160SCMLB |

| Rear Cover Type | Round Type |

| Mounting Type | Axial Mounting Bracket |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <20mm> |

| Stroke | 160mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.